Monitor. Detect. Resolve.

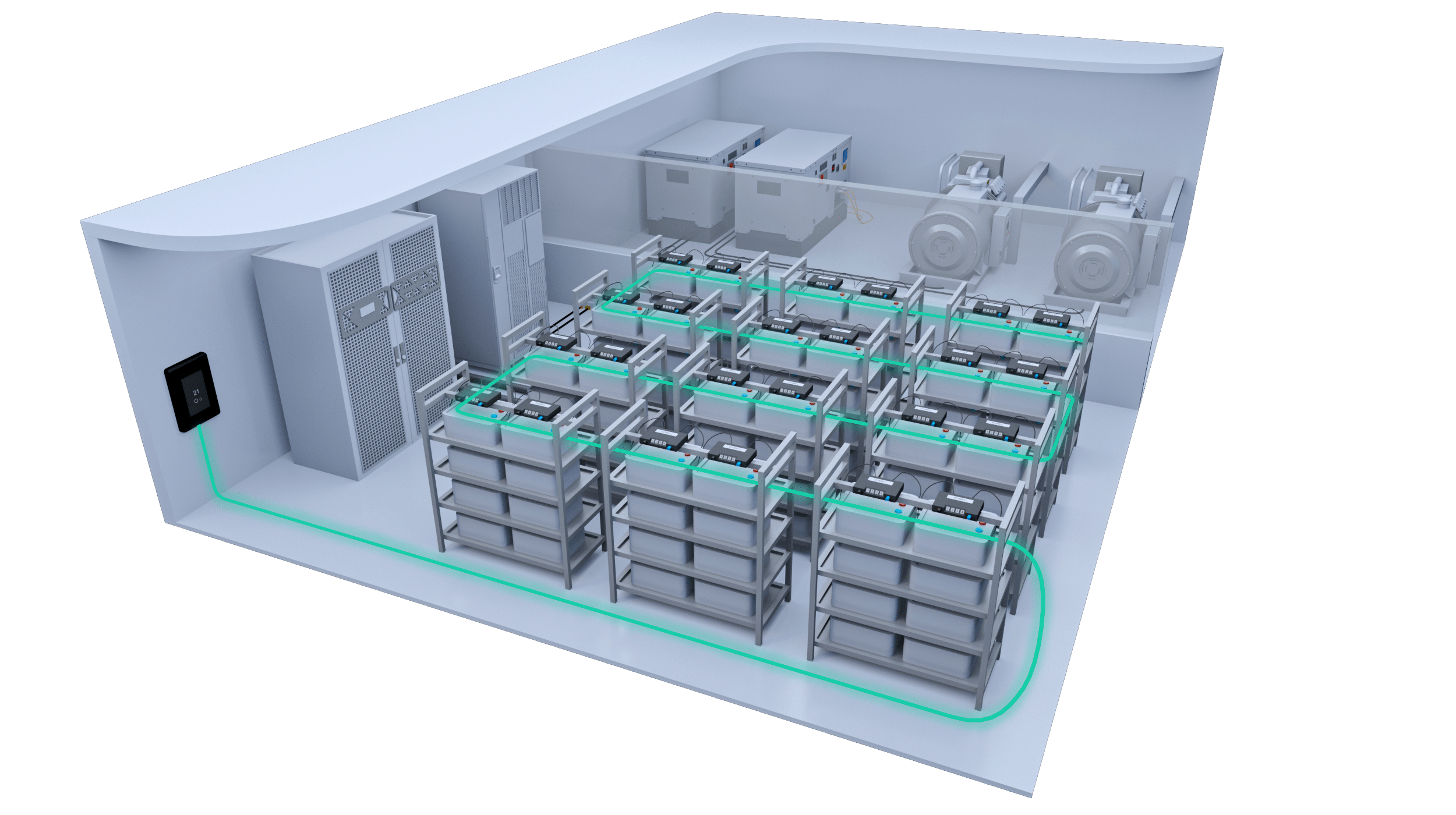

Cellwatch Battery Monitoring is Parameter’s core battery maintenance platform, trusted for more than 30 years in mission-critical environments. It delivers continuous visibility into the health of every battery cell in a critical power string. Built on proven technical innovation and trusted by utilities, hyperscale data centers, and global enterprise networks, Cellwatch provides early failure detection, deterministic alarms, and actionable insight without taking the system offline.

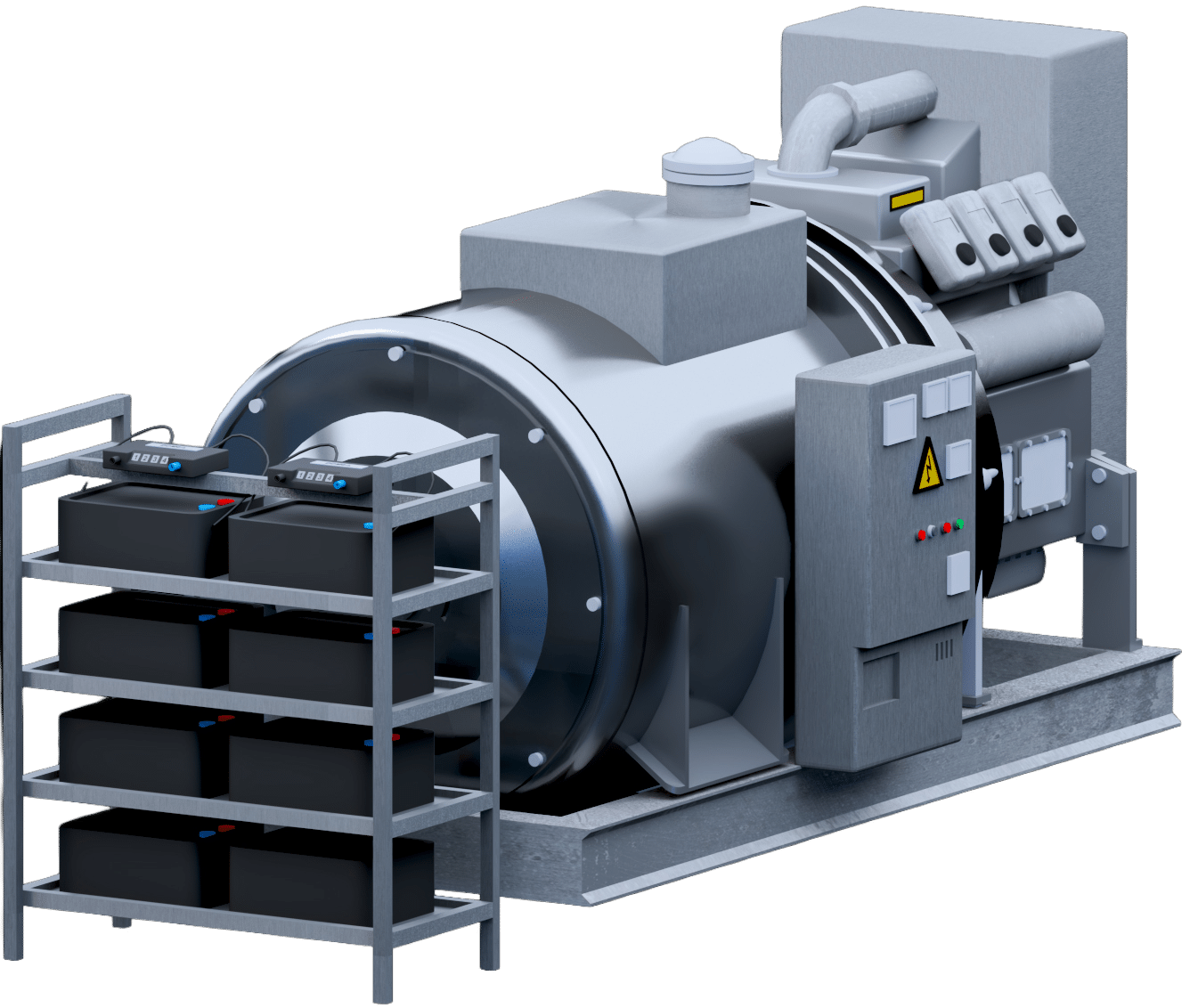

Cellwatch operates as an always-on monitoring architecture that detects failure modes early and helps keep battery strings reliable. It supports Uninterruptible Power Supply (UPS) backed operations as well as other critical battery systems, including communications, transfer switch, and generator start batteries.

Our Technology Supports

- EMI-resistant architecture with signal buffering for challenging environments

- BACnet, Modbus, and SNMP integration

- Scalable architecture for subfloor, overhead, or distributed layouts

- Granular Configurable leak threshold control with signal buffering (10–300μA) to minimize false positives

- Real-time leak alerts with auto-reset logic via email and direct to BMS

- Fully autonomous —Supports standalone operation with web interface with no cloud or subscriptions required

- Pinpoint accuracy across long cable runs

Built On a Legacy of Trust

Cellwatch was the first commercial system designed to make daily battery diagnostics practical on a large scale.

1st to build a fully modular battery monitoring system.

1st to build a scalable system.

1st to introduce daily battery monitoring.

1st to provide a fiber-optic interconnect system

1st to develop a self-addressable system.

1st to automate ohmic value setting.

Proven at Scale in Mission-Critical Environments

Cellwatch Battery Monitoring by Parameter is trusted worldwide to monitor mission-critical power systems. Since its release, it has monitored over 2 million batteries and 10 million cells worldwide

Countries Cellwatch Services

The measurement set and tools integrated into Cellwatch align with IEEE stationary battery maintenance practices. Parameter engineers also contribute to IEEE Standards working groups that shape industry best practices for all battery types, ensuring our products continue to reflect current best practices.

Trusted Across Industries:

Leading Hyperscalers

Global AI Infrastructure

Cloud Platform Partners

Federal Emergency Networks

Organizations that operate large critical-power fleets use Cellwatch to execute daily diagnostics at scale, with consistent measurements, low service overhead, and durable hardware that remains in place across their lifecycles.

Critical Power System

The example below shows a standard critical power system. and demonstrates how a live facility is impacted by different system failures.

Click to disable the system’s batteries, utility power supply, or generator fuel and see how the system reacts.

As you can see, back up batteries are crucial to preventing downtime during a critical power failure. Even a single failed cell can compromise an entire string and leave your system vulnerable. Recognizing these threats immedately is key to ensuring reliable uptime.

Click here to see why industry-standard battery monitoring methods put your system at severe risk.

Continuous VS Periodic Monitoring

Many facilities continue to rely on handheld testers or scheduled maintenance visits to check batteries. These methods provide only a limited set of snapshots over the life of the battery, and the results can vary depending on the meter calibration, the quality of the connection, and the inconsistency of technician.

Between those visits, a cell can appear to maintain a normal float voltage yet deteriorate to the point of failure. While cell degradation often takes weeks, in some VRLA systems this can happen in as little as two days, so a failed cell may remain in service until the next PM cycle.

Battery Systems Offline

This rapid failure highlights the importance of monitoring the key parameters of the battery on a regular basis.

This approach also creates safety risks, as it requires the use of protective equipment and physical exposure to energized terminals and acid. Alternatively, these visits often require battery systems to be taken offline for manual measurements.

Real-Time monitoring under live conditions

Cellwatch Battery Monitoring eliminates these gaps by operating as a continuously scanning and permanently installed system. Unlike manual approaches that attempt to control or intervene in the system, Cellwatch continuously measures without intrusion.

Manual methods, such as handheld meter testing every 90 or 180 days, leave significant blind spots and yield inconsistent results. Active continuous monitoring provides consistent visibility under real operating conditions, making deterioration clear as it develops rather than after a battery string is compromised. This ensures the system is never at risk.

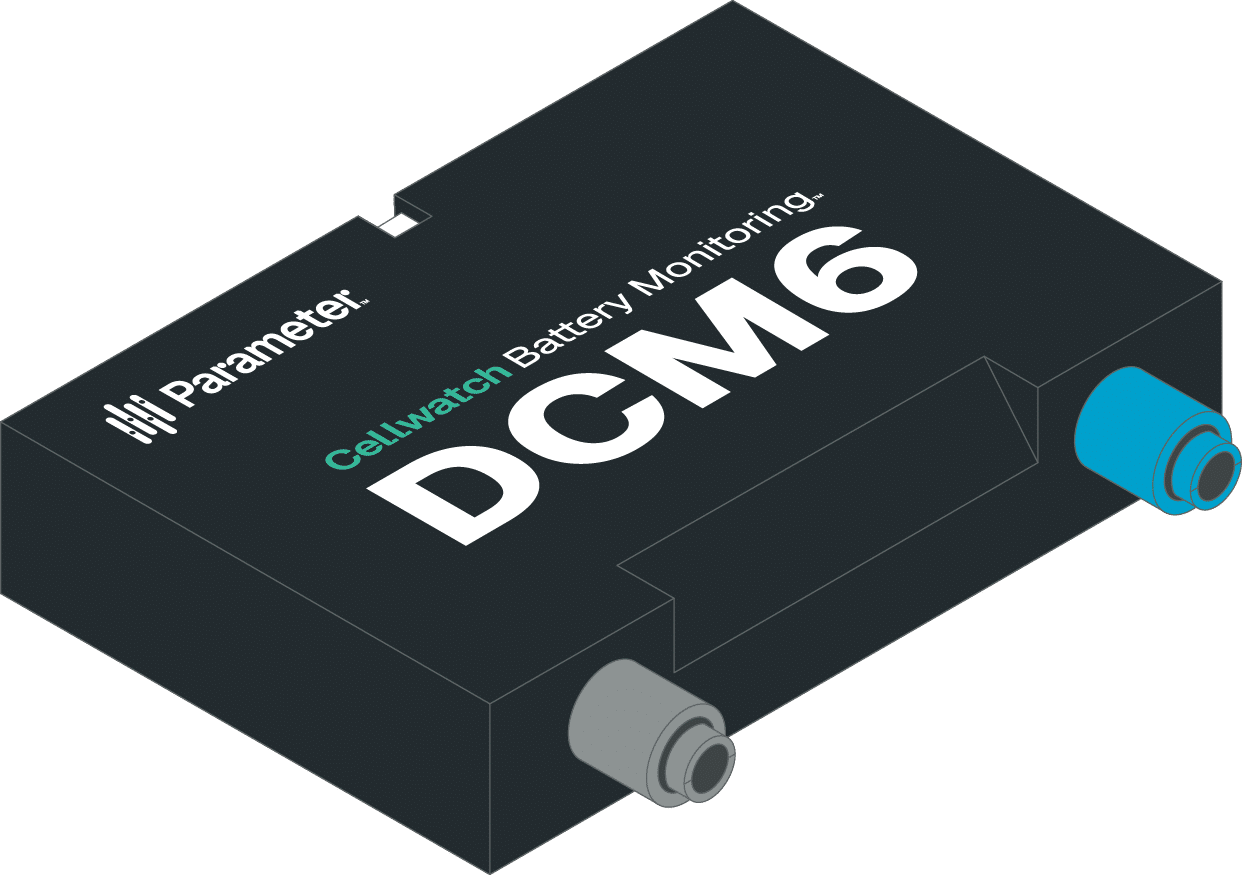

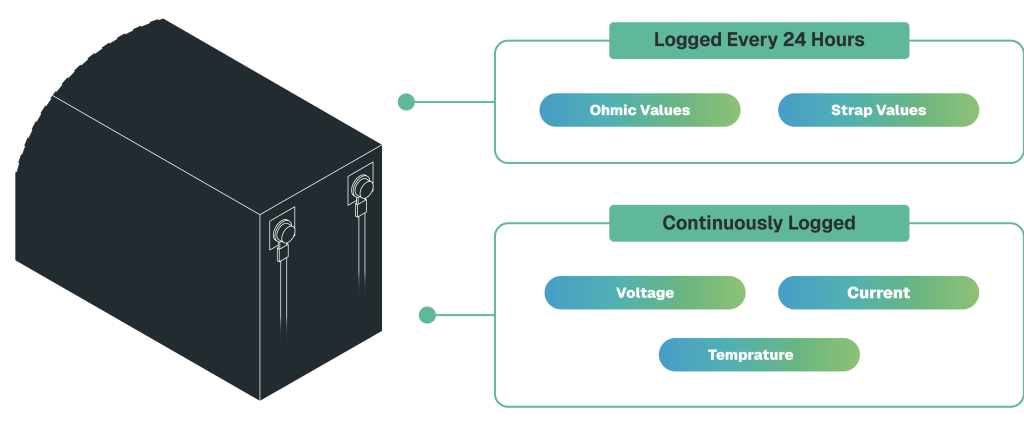

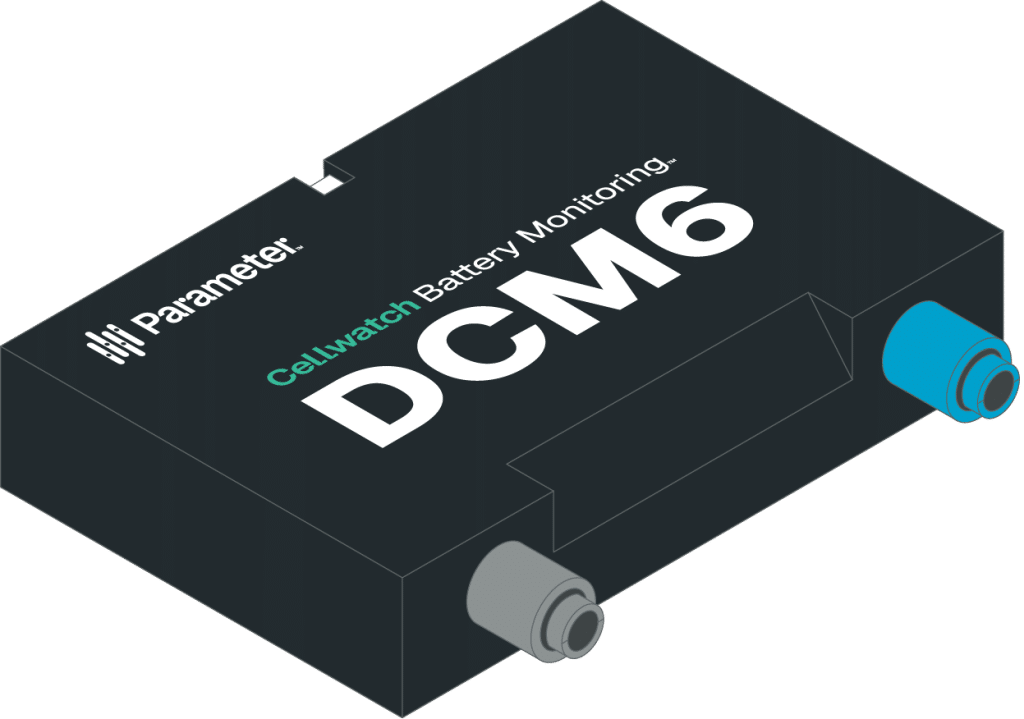

The architecture is built on the Data Collection Module (DCM), now in its sixth generation. DCMs include interchangeable harnesses and high-precision, repeatable measurements. They track voltage, ohmic value, temperature, and strap resistance without requiring the batteries to be taken offline. Installation is easy, requiring no invasive probes or manual addressing.

Strap and terminal resistance readings indicate the tightness and condition of the connections between batteries. If those numbers rise, it often means the connection has become high resistance, which creates hot spots under high-current events and can lead to premature failure of the string.

Proactive Maintenance

Cellwatch continuously measures battery status during charging and discharging phases.

During discharge, when the batteries are supporting their critical loads, the system performs rapid continuous scans to capture how each cell behaves under stress.

Taken together, these measurements provide a comprehensive view of performance and reveal weak cells before they threaten system stability. The design filters noise and reduces nuisance alarms that are common in lower-grade systems.

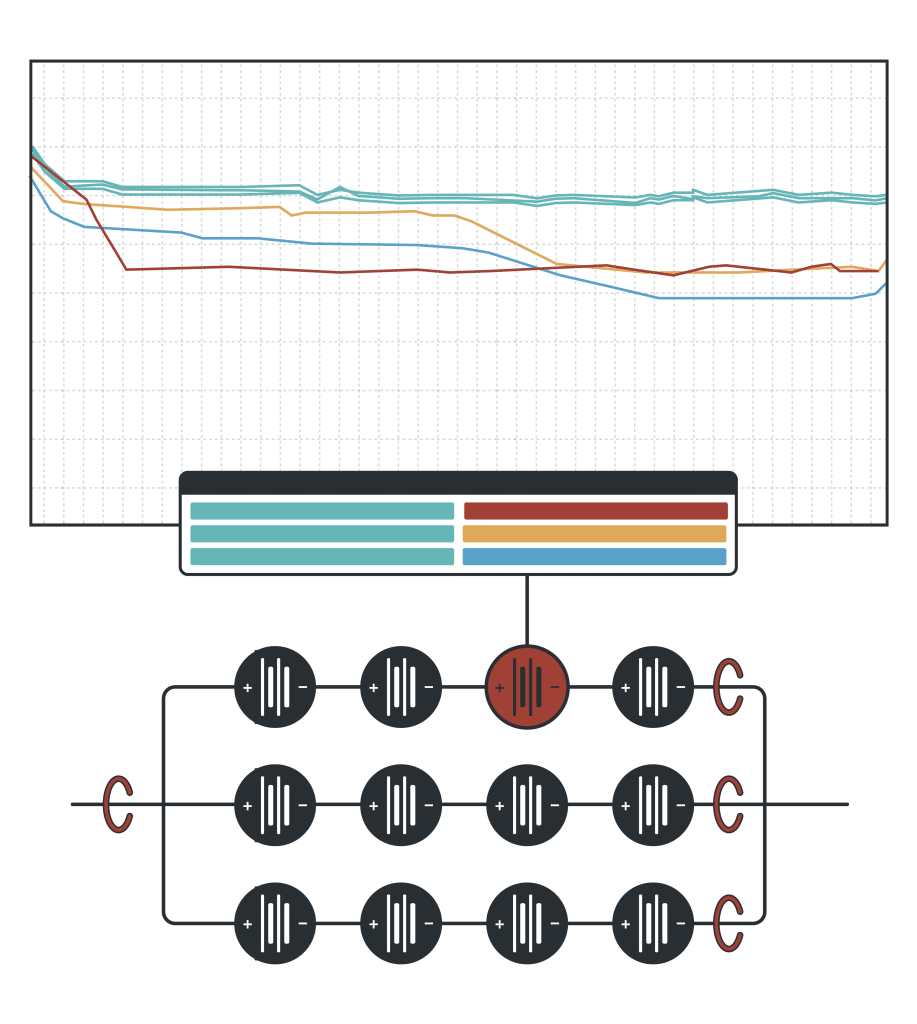

Cell-Level Discharge and Resistance Readings

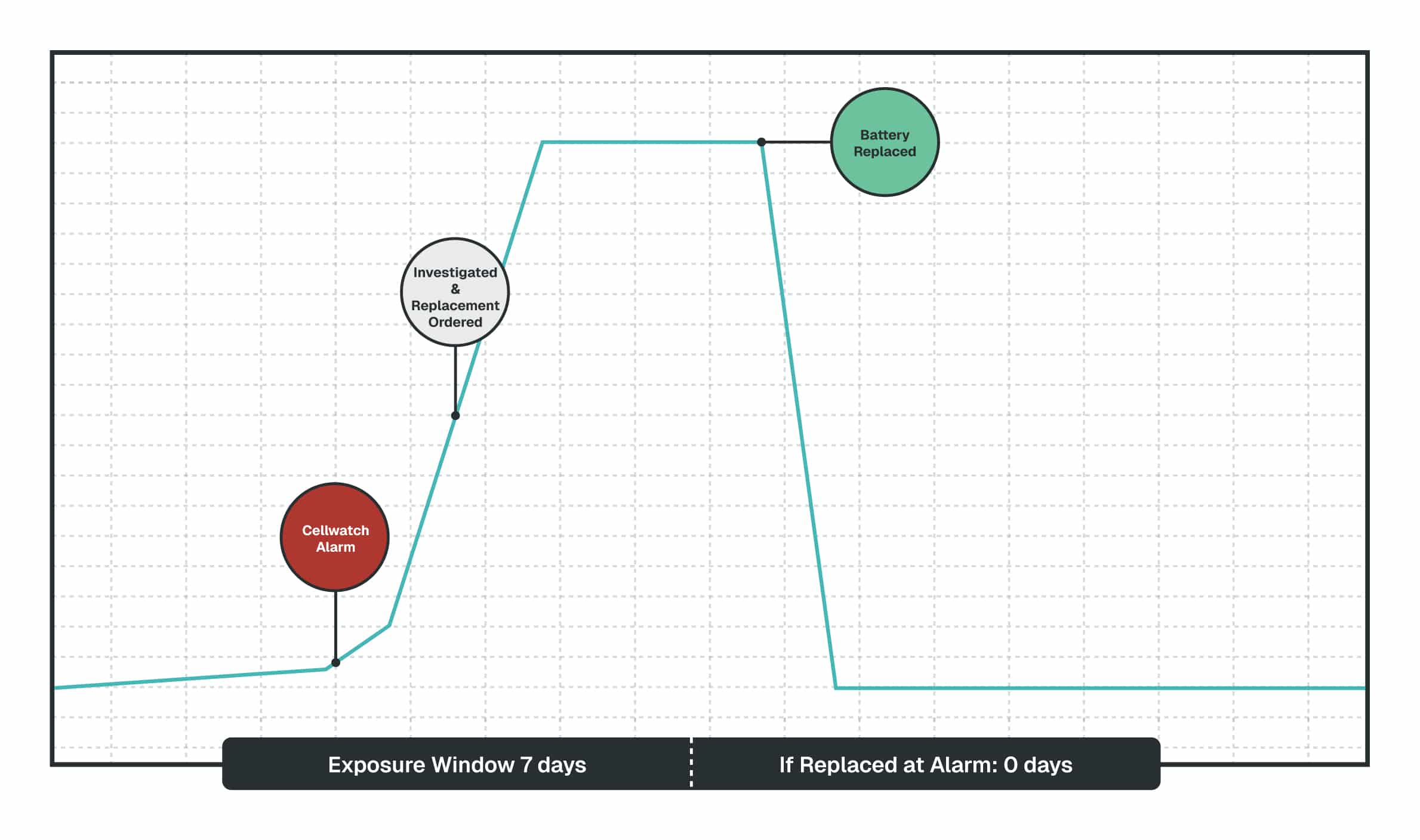

See below a real-world example of Cellwatch in action from one of our clients.

The graph depicts the ohmic value of a critical string battery, indicating cell failure. The moment cell health started to decline, our system sent out an alert. The battery had completely failed, compromising the entire string within just two days.

With periodic maintenance, the client would have gone months without knowing their UPS system was completely offline.

Instead, the 3 month vulnerability was reduced to 7 days.

And if the battery had been replaced when the alarm went off, the system would have completely avoided vulnerability.

Operational impact

Continuous monitoring has become an accepted standard of care in mission-critical environments because it directly contributes to operational stability and reliability.

By monitoring voltage and temperature in real-time, and trending ohmic value daily, Cellwatch enables engineers to detect loose connections, identify failing cells, and take action before issues escalate into string failures. This approach shifts maintenance from reactive to proactive, reduces unnecessary replacements, and lowers battery costs.

Why Choose Parameter?

Click below to learn why Parameter is the leading solution for environment monitoring in critical applications.

Built for Longevity

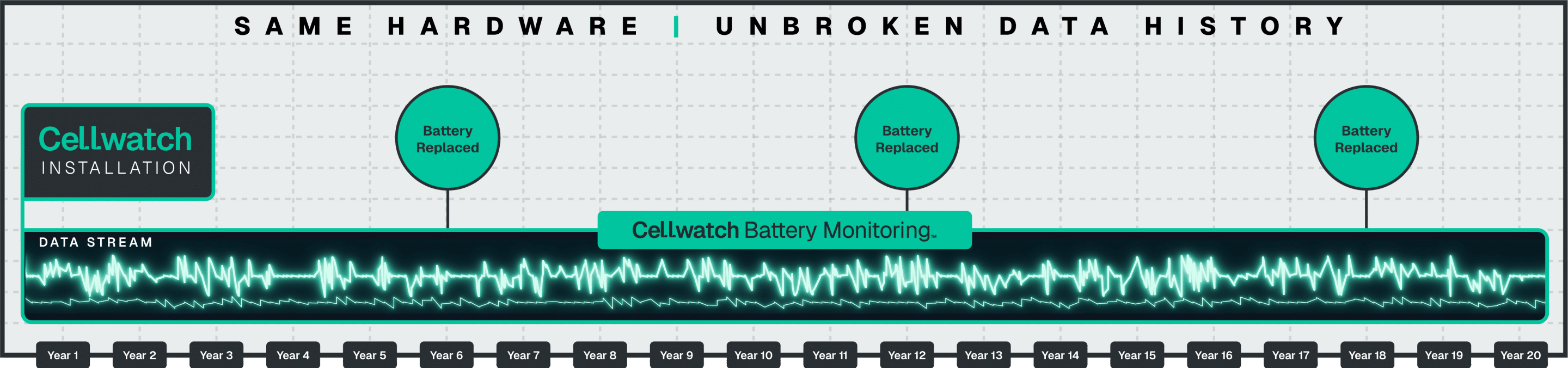

Cellwatch Battery Monitoring is engineered to remain in place across multiple battery lifecycles. The monitoring hardware is not tied to a specific battery chemistry or string configuration, so when cells are replaced, the same DCMs and iBMU continue to operate without reprogramming or rewiring.

The Cellwatch hardware is designed for longevity and to outlast the lifespan of the installed battery system. Historical records will reflect battery replacements as well as expansions and contractions as the battery deployment changes over the lifetime of the battery monitoring system. These historical records can be used to compare battery performance, detect changes in the operating environment, and assist audits.

Long-term reliability also reduces cost. Reliability is documented at the component level, with DCMs rated for mean time between failure in centuries, not years. In practice, most modules remain in service across multiple battery replacement cycles.

Hardware that lasts across two or three battery lifecycles avoids the expense of reinstalling a new monitoring system with each replacement, and fewer commissioning cycles mean less labor. By reusing the same architecture, operators lower the total lifecycle cost of ownership while maintaining uninterrupted visibility into critical power infrastructure.

Detects What Others Miss

Cellwatch Battery Monitoring measures ohmic value at the micro-ohm level, providing early warning weeks or months before a failure event. Micro-ohm precision gives users better insight into their batteries, allowing them to extend the useful life of the battery. Without adequate resolution and resilience in high-noise environments, lower-precision monitors can lose accuracy as measurements approach alarm thresholds, which masks early deterioration.

Cell or Unit Ohmic Value and strap values are logged automatically at least every 24 hours, while voltage, current, and temperature are monitored continuously.

This creates a consistent dataset that shows deterioration in real operating conditions, pinpoints the affected cell, and indicates when corrective action is needed.

With this visibility, operators can target replacement to the cells at risk, extend the life of the balance of the string, and prevent failures that lead to costly downtime. The outcome is fewer outages, longer service life, and higher operational efficiency across the battery system.

Top Reasons for Battery Failure:

Installation

Connection issues, installation errors, loose inter-cell links.

Ageing

Wear-out, dry-out, cracking, leaking.

Charging / Maintenance

Improper charging, cell failure, lack of PMs.

Human Element

Operational mistakes, human errors.

Environmental Risks

Thermal risks, poor temperature control, thermal runaway.

Catastrophy

Shorts/opens, infant mortality, noise.

Primary

Supporting

N/A

Failure Cause |

Voltage (V) |

Current (I) |

Temperature (T) |

Ohmic Value |

Strap Resistance |

Discharge Behavior |

|---|---|---|---|---|---|---|

Failure Cause |

Voltage (V)

R

|

Current (I)

R

|

Temperature (T)

R

|

Ohmic Value

R

|

Strap Resistance

|

Discharge Behavior

R

|

Failure Cause |

Voltage (V)

|

Current (I)

|

Temperature (T)

|

Ohmic Value

|

Strap Resistance

|

Discharge Behavior

|

Failure Cause |

Voltage (V)

|

Current (I)

|

Temperature (T)

|

Ohmic Value

|

Strap Resistance

|

Discharge Behavior

|

Failure Cause |

Voltage (V)

|

Current (I)

|

Temperature (T)

|

Ohmic Value

|

Strap Resistance

|

Discharge Behavior

|

Failure CauseHuman, operational |

Voltage (V)

|

Current (I)

|

Temperature (T)

|

Ohmic Value

|

Strap Resistance

|

Discharge Behavior

|

Failure CauseCatastrophic, random |

Voltage (V)

|

Current (I)

|

Temperature (T)

|

Ohmic Value

|

Strap Resistance

|

Discharge Behavior

|

Reduces Cost, Risk, and Uncertainty

By shifting from time-based to condition-based maintenance, Cellwatch eliminates premature battery replacement and reduces site labor. Real-time alarms prevent cascading failures, and automated data logs support audit readiness and compliance tracking.

For many users, the return on investment is realized within 18 to 36 months.

- Use the calculator below to estimate Cellwatch's ROI in your operation.

- Input the size of your operation for an instant estimate of your cost savings with Cellwatch Battery Monitoring

Though our systems can provide positive ROI even without factoring in loss prevention, the greater value is in preventing just one critical failure. A single poor strap can cause an entire load to fail, and one outage can result in hundreds of thousands of dollars, and in many cases millions, in lost revenue, fines, or damage to reputation. Industry studies show that 75 percent of UPS failures are battery-related. With average outages costing $11,000 per minute and lasting nearly 90 minutes, one event can exceed $1 million in impact.

Cellwatch is unmatched in preventing these failures, making it the most effective protection policy for critical operations. It also delivers positive ROI through fewer site visits, extended battery life, and preventing outages.

Prevent Generator Transfer Failures

Generator transfer is one of the most demanding moments during a data-center outage.

If the generator fails to start due to a bad battery, the entire data center can be at risk of a long-duration outage.

Cellwatch provides evidence of string readiness prior to the transfer and reduces ride-through risk during generator start and stabilization.

Product Specifications & Components

Monitoring Architecture

Cellwatch Battery Monitoring is built to be modular, flexible, and easily scalable. The monitoring platform is chemistry agnostic and can monitor different systems and battery types to provide a centralized report of battery health across your entire operation.

Our system integrates seamlessly with building management systems (BMS) and supervisory control and data acquisition (SCADA) platforms using open protocols. It natively supports Modbus RTU/TCP IP and SNMP. Alarm thresholds, polling intervals, and output triggers are fully customizable, with alarms sent via relays, trap notifications (SNMP/DNP3), or globally centralized dashboards using the Cellwatch Central software are also available.

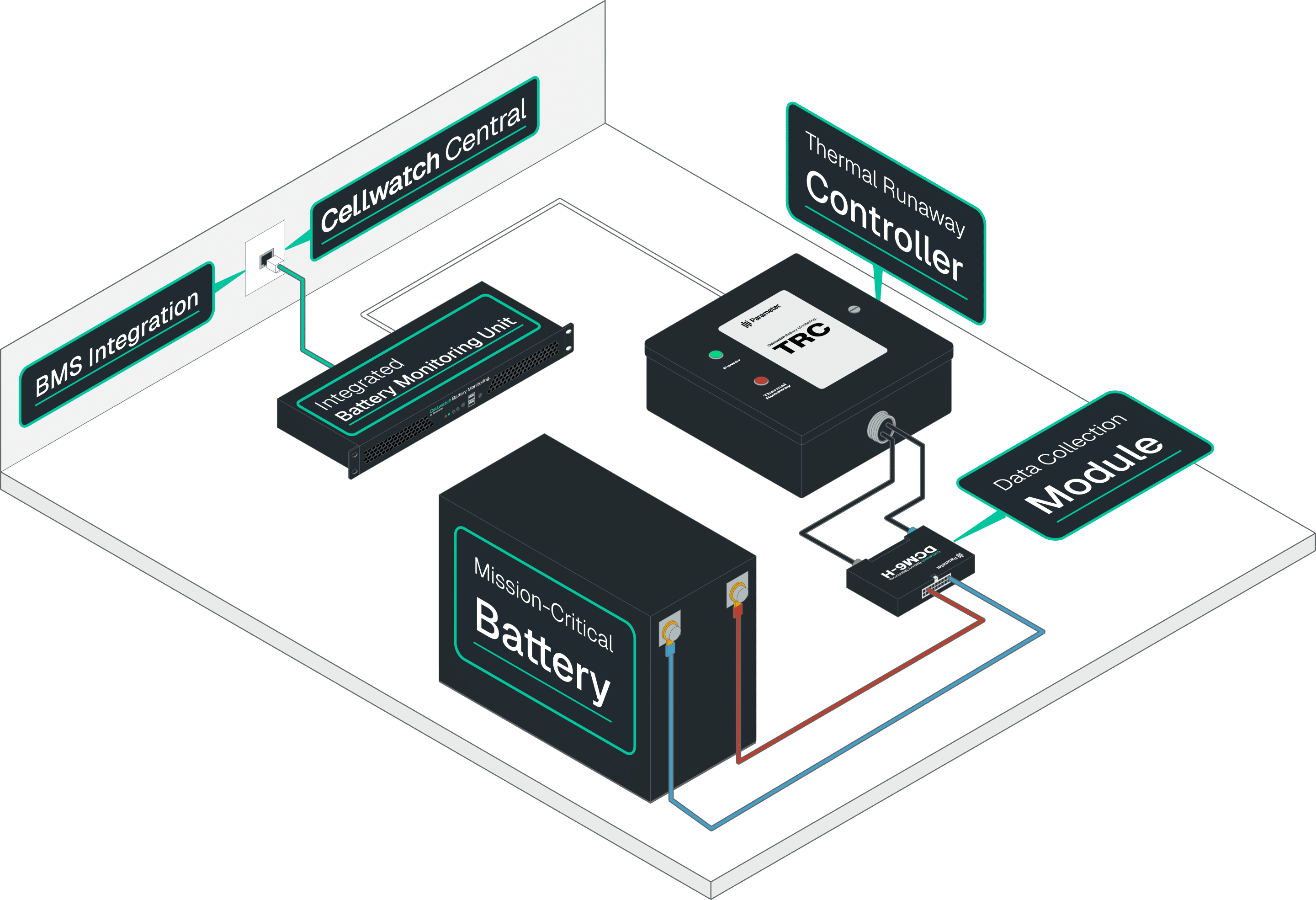

System Components

DCM

Data Collection Modules

Solid state, optically isolated, fiber optic cell-monitoring units.

iBMU

Integrated Battery Monitoring Unit

Centralized battery monitoring hub connecting control units to BMS.

CT

Current Transducers

Sensors clamp over string wiring to measure discharge, recharge, and float current.

CU

Control Unit

String-level system management bridging communication from DCM to iMBU.

TRC

Thermal Runaway Controller

String-level Control Unit monitoring for early signs of thermal runaway.

TT

Temperature Transducers

Sensors track ambient and pilot cell temperatures.

Each component is modular and plug-and-play, avoiding the need for site-specific engineering or complicated commissioning. This architecture ensures long-term reliability and scalability in mission-critical facilities.

Component |

Function |

Monitoring Scope |

Specs |

|---|---|---|---|

Component |

FunctionCell-level monitoring |

Monitoring ScopeVoltage, internal resistance (ohmic value), temperature, strap resistance |

Specs1 DCM per 4 cells; fiber-optically isolated for safety |

Component |

FunctionString-level monitoring |

Monitoring ScopeAggregates up to 4 strings |

SpecsCommunicates with up to 254 DCMs; supports CTs & TTs |

Component |

FunctionSystem brain + interface |

Monitoring ScopeCentralized system control |

SpecsManages up to 31 CUs; supports thousands of channels across large-scale deployments |

Component |

FunctionString-level monitoring and safety |

Monitoring ScopeThermal anomaly detection |

SpecsControl Unit (CU) functionality. Additionally, can disconnect up to 4 strings under thermal runaway conditions |

Component |

FunctionString current monitoring |

Monitoring ScopeFloat, recharge, and discharge currents |

SpecsSupports +/-1000A, current scaling available |

Component |

FunctionAmbient and pilot cell monitoring |

Monitoring ScopeCell-level or ambient temperature |

Specs2°C to +80°C operating range |

Component |

FunctionEnterprise-wide visibility |

Monitoring ScopeMulti-site integration |

SpecsMonitors 50,000+ cells across multiple facilities; unified reporting and trending |

Component |

FunctionSystem interoperability |

Monitoring ScopeSCADA / BMS integration |

SpecsModbus TCP/IP, SNMP |

Component |

FunctionRegulatory alignment |

Monitoring ScopeIndustry standards |

SpecsUL/CE certified; optically isolated for technician safety |

System Architecture

Data Collection Modules

Mounted directly on battery containers, each Data Collection Module (DCM) measures voltage, internal resistance (ohmic value), temperature, and strap resistance of the connected cell(s).

Each DCM is powered by the monitored cells and communicates over a fiber optic daisy loop, which provides electrical isolation and eliminates termination and addressing steps.

Our system offers DCM models optimized for high voltage, low voltage, ripple voltage, and short strings.

DCM Model |

Use Case |

Monitoring Scope |

Measurement Ranges |

|---|---|---|---|

DCM Model |

Use Case2‑volt cells, low-voltage strings (VRLA or Ni-Cd) |

Monitoring ScopeVoltage, Ohmic Value, Temperature (optional) |

Measurement RangesVoltage 0–12 V; Ohmic 0–5 mΩ; Temp 2–80 ºC |

DCM Model |

Use CaseHigher-voltage jars 4–16 V, VRLA or Ni-Cd |

Monitoring ScopeVoltage, Ohmic Value, Ripple, Temperature (optional) |

Measurement RangesVoltage 0–80 V; Ohmic 1–50 mΩ; Ripple 0–400 mVAC rms; Temp 2–80 ºC |

DCM Model |

Use CaseString-wide ripple and string voltage on high-voltage strings |

Monitoring ScopeRipple Voltage (string), String Voltage |

Measurement RangesRipple 0–5 VAC rms; String 24–300 VDC |

DCM ModelDCM5T-DS (DCM-DS) |

Use CaseCharger‑cable connection resistance monitoring |

Monitoring ScopeVoltage, Ohmic Value, Temperature (optional), Ripple across 4 jars |

Measurement RangesVoltage 0–60 V; Ohmic 1–65 mΩ; Temp 2–80 ºC; Ripple 0–4 Vrms (40 Hz–1 kHz) |

DCM ModelDCM6-L-CC |

Use CaseString current monitoring |

Monitoring ScopeOhmic Value (strap/cable), supports enhanced precision |

Measurement RangesOhmic 0–5 mΩ |

Control Unit

The Control Unit (CU) manages communication, alarms, and integration across the entire Cellwatch system. With flexible interfaces and proven reliability, the Control Unit provides the foundation for large-scale battery deployments.

DCMs communicate with the CU, which operates at the string level, monitoring up to 4 strings. The CU aggregates inputs from up to 254 DCMs, as well as CTs and TTs, and provides multiple alarm contacts for local integration.

The CU offers system-level management of battery monitoring at the string level, flexible integration with multiple DCMs across large installations, and coordinated alarm and relay control for complex power systems

Thermal Runaway Controller

The Thermal Runaway Controller (TRC) delivers string-level thermal safety by combining continuous monitoring with 10 relay outputs for protective response. Built for mission-critical facilities, it provides the confidence operators need when safety cannot be compromised.

Used with the Cellwatch system, it adds protection against Thermal Runaway events. It can disconnect up to four strings based on a proven algorithm to eliminate the thermal runaway event by early detection and prevention.

The TRC offers monitoring for early signs of thermal runaway and rapid disconnect response, integration of thermal safety controls into mission-critical environments, and high relay capacity to support large or complex battery systems.

Integrated Battery Monitoring Unit

The Integrated Battery Monitoring Unit (iBMU) brings every Cellwatch module together into one central hub. With built-in remote access, multiple communication interfaces, and ready-to-go licensing, it delivers complete oversight from a single point of control.

Serving as the system master, this controller manages up to 31 Control Units, consolidates data across large deployments, stores system history, and provides the primary interface to BMS and SCADA platforms.

The iBMU provides seamless integration of data and communication for large systems and remote access a for distributed or unmanned facilities.

Accessory Components

Cellwatch Battery Monitoring is a modular system that is customized to suit each application. In addition to our core modules, we offer a suite of optional and supporting equipment to provide added value in line with your specific concerns and limitations. Our most popular add-ons include:

Current Transducers

Clamp over string wiring to measure discharge, recharge, and float current.

Temperature Transducers

Track ambient and pilot cell temperatures to support thermal risk analysis.

GenStart Kit

Extends monitoring coverage to generator starter batteries for complete power-path visibility.

Contact us to learn more about how our accessory products can augment your application.

For custom capabilities and manufacturing, reach out to our OEM team directly to discuss how we can augment your application.

Tailored for networks with numerous small, often remote sites, this battery monitoring variant includes electrolyte-level sensing, ground-fault detection, ripple monitoring, and automated NERC PRC-005 compliance reporting. The Frontier system is highly customizable depending on the requirements or needs for each remote monitoring location.

Utilities using the Frontier Battery Monitoring System meet NERC PRC-005 compliance requirements through automated daily reporting instead of on-site testing. Applications in these environments must maintain high reliability, precise and accurate measurements, in a wide range of environmental conditions.

With 30 years of experience and multiple generations of DCM modules, the Frontier Battery Monitoring System provides a hardened system while maintaining a light impact to the battery so the remote battery system can operate unmanned for days

Key Advantages

NERC Reporting

Automated daily NERC reports increase the ease of maintaining NERC compliance.

Cost Savings

Real-time visibility into battery performance maximizes useful battery life and decreases the need for onsite visits.

Preemptive Maintenance

Streamlined preemptive maintenance to increase backup power reliability.

Remote Monitoring

A secure centralized battery monitoring platform ensures smooth and secure operations across a network of remote facilites.

This compact, field-configurable unit supports typical building and industrial protocols, installs easily in panels or racks, and operates with no recurring license or integration fees.