Monitor. Detect. Resolve.

Built on a legacy of reliability and engineered for the future, Parameter’s RLE leak detection systems deliver precision, integration, and rugged performance in the most demanding environments.

From hyperscale facilities to healthcare infrastructure, our sensing systems are trusted to identify leaks before they become disasters with real-time location accuracy, BMS-native integration, and resilient hardware that stands the test of time.

Our Technology Supports

- EMI-resistant architecture for challenging environments

- Pinpoint accuracy across long cable runs

- Real-time leak alerts via email and direct to BMS

- Configurable leak threshold control with signal buffering (10–300μA) to minimize false positives

- Real-time leak alerts with auto-reset logic via email and direct to BMS

- Scalable architecture for subfloor, overhead, or distributed layouts

- Direct integration with BACnet, Modbus, and SNMP

Built On a Legacy of Trust

RLE’s leak detection systems are deployed in mission-critical facilities worldwide, ranging from global cloud platforms to government installations. We’re not just another vendor; we’re trusted partners to industry leaders, providing embedded solutions worldwide that facilitate increased uptime, compliance, and operational continuity.

Trusted Across Industries:

Leading Hyperscalers

Global AI Infrastructure

Cloud Platform Partners

Federal Emergency Networks

Parameter’s leak detection system delivers on three core engineering priorities:

Pinpoint Accuracy, Rock-Solid Reliability, and Seamless Integration.

Why Choose Parameter?

Click below to learn why Parameter is the leading solution for leak detection in critical applications.

Accuracy

The Parameter RLE Leak Detection system delivers highly accurate fault detection, pinpointing events to within 0.5% for 10,000 feet of sensing cable.

Our controllers support sensitivity adjustments to minimize unwanted alerts. This lets the user set a low threshold for mission-critical areas while also allowing a higher threshold to suppress nuisance alarms from condensation. Unlike spot detectors or fixed-threshold systems, Parameter RLE distance read controllers report the exact location of fluid contact along their entire run while minimizing unwanted alarms.

The Parameter RLE Leak Detection system delivers highly accurate fault detection, pinpointing events to within 0.5% for 10,000 feet of sensing cable.

Our controllers support sensitivity adjustments to minimize unwanted alerts. This lets the user set a low threshold for mission-critical areas while also allowing a higher threshold to suppress nuisance alarms from condensation. Unlike spot detectors or fixed-threshold systems, Parameter RLE distance read controllers report the exact location of fluid contact along their entire run while minimizing unwanted alarms.

This enables precise mapping in distributed architectures, including subfloor, ceiling, or remote infrastructure placements. Whether the cable is 10 feet or 10,000, you’ll know exactly where a leak started. That means faster response, fewer false alarms, and greater confidence that when an alarm triggers, you know where to go and why.

Reliability

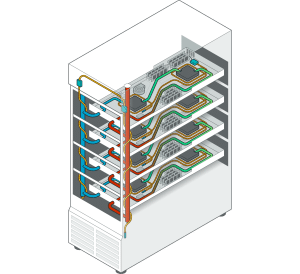

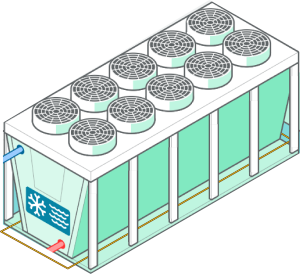

Parameter’s leak detection systems are engineered for long-term reliability, and are therefore excellent wherever false alarms and hardware failure are unacceptable. Our distance read technology is designed to minimize disruption and deliver stable performance whether you’re running sensing cable beneath raised floors, on overhead piping, in leak trays, CRACs, CRAHs, CDUs, other HVAC components or UPS systems or anywhere fluids are unwanted.

Accurate Leak Detection in High-Noise Environments

- Each controller actively filters out signal interference, delivering a stable and EMI-resistant design. This provides leak detection integrity in high-noise environments without compromising sensitivity

- With adjustable thresholds, engineers can tune the system to suppress environmental interference while still detecting small fluid events with precision.

Hardware Longevity

The hardware itself is built to last. Parameter controllers with web interfaces have no cloud dependency or subscription lock-ins. Firmware doesn’t expire, and systems don’t require periodic replacements to maintain functionality.

Some of our deployed units have been active for over 15 years. They remain fully operational, and continue to be trusted in the field.

Cables are manufactured to withstand harsh deployment conditions. From chemical-resistant and low-smoke, zero-halogen variants to rodent-resistant options for retrofit or industrial sites, the materials are selected for application-specific durability. Combined with high uptime and minimal required maintenance, Parameter systems are trusted by facilities teams who need infrastructure that works for years, not just through the next product cycle.

Integration

Our leak detection systems are designed to seamlessly integrate into the operational backbone of any facility, without compromising functionality or performance. Each controller supports multiple BMS communication protocols, including BACnet MS/TP (RS-485), BACnet IP, Modbus RTU (RS-485), Modbus TCP, and SNMP ensuring seamless integration that is never limited by legacy infrastructure or proprietary standards.

Because facilities vary widely in how they implement building management, ranging from centralized server-based platforms to distributed field networks, our systems offer flexible deployment options. Whether installed as standalone or fully networked nodes, controllers can relay status, alerts, and location data in real time to the BMS.

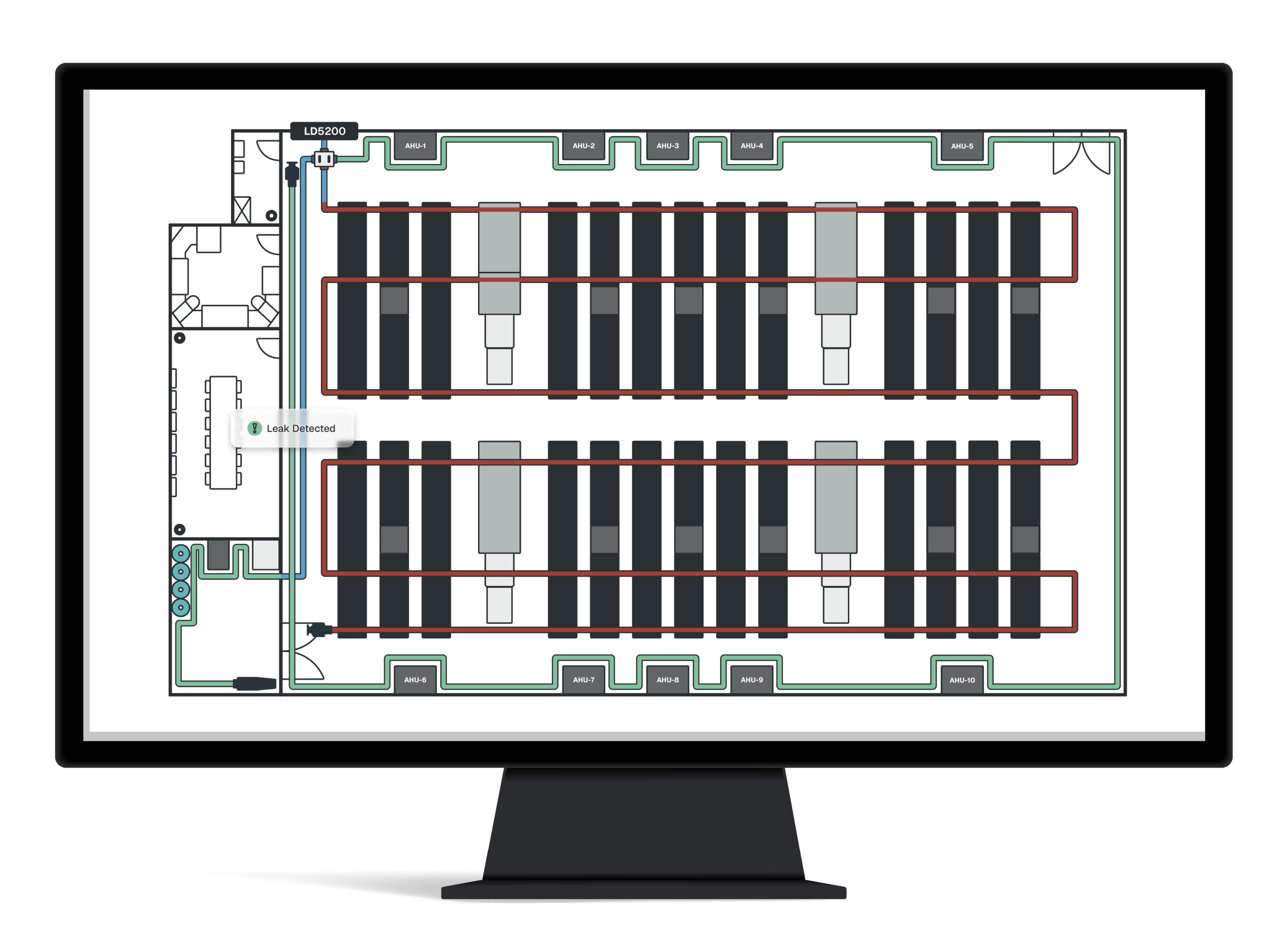

This allows operators to effortlessly centralize alarm management, automate facility responses, and easily track everything across floor plans, racks, or facilities—no extra middleware or translation layers are needed.

Compatible Protocols:

BACnet

ModBus

SNMP

TCP/IP

Supported Features Include:

- Support for both direct-to-BMS alerting as well as controller aggregation via master/client controller mode.

- Direct-to-BMS mapping for precise and fast leak identification and location.

- Threshold tuning to reduce false alarms in high-humidity or harsh environments

- Controllers support both latching mode (manual reset required) and non-latching mode (alert clears when cable is dry).

This combination of communication flexibility, architectural adaptability, and real-world install simplicity makes Parameter’s integration approach trusted by OEM partners and enterprise operators alike.

Product Specifications & Components

Controllers

Parameter controllers detect leaks, localize the source, and communicate alerts across your facility’s infrastructure. They are designed to meet diverse facility requirements, catering to everything from small-scale installations to large hyperscale data centers.

Our controllers are compatible with leading BMS and Data Center Infrastructure Management (DCIM) tools, allowing for seamless integration. Additionally, they feature adjustable detection thresholds, enabling customization to suit specific environmental conditions.

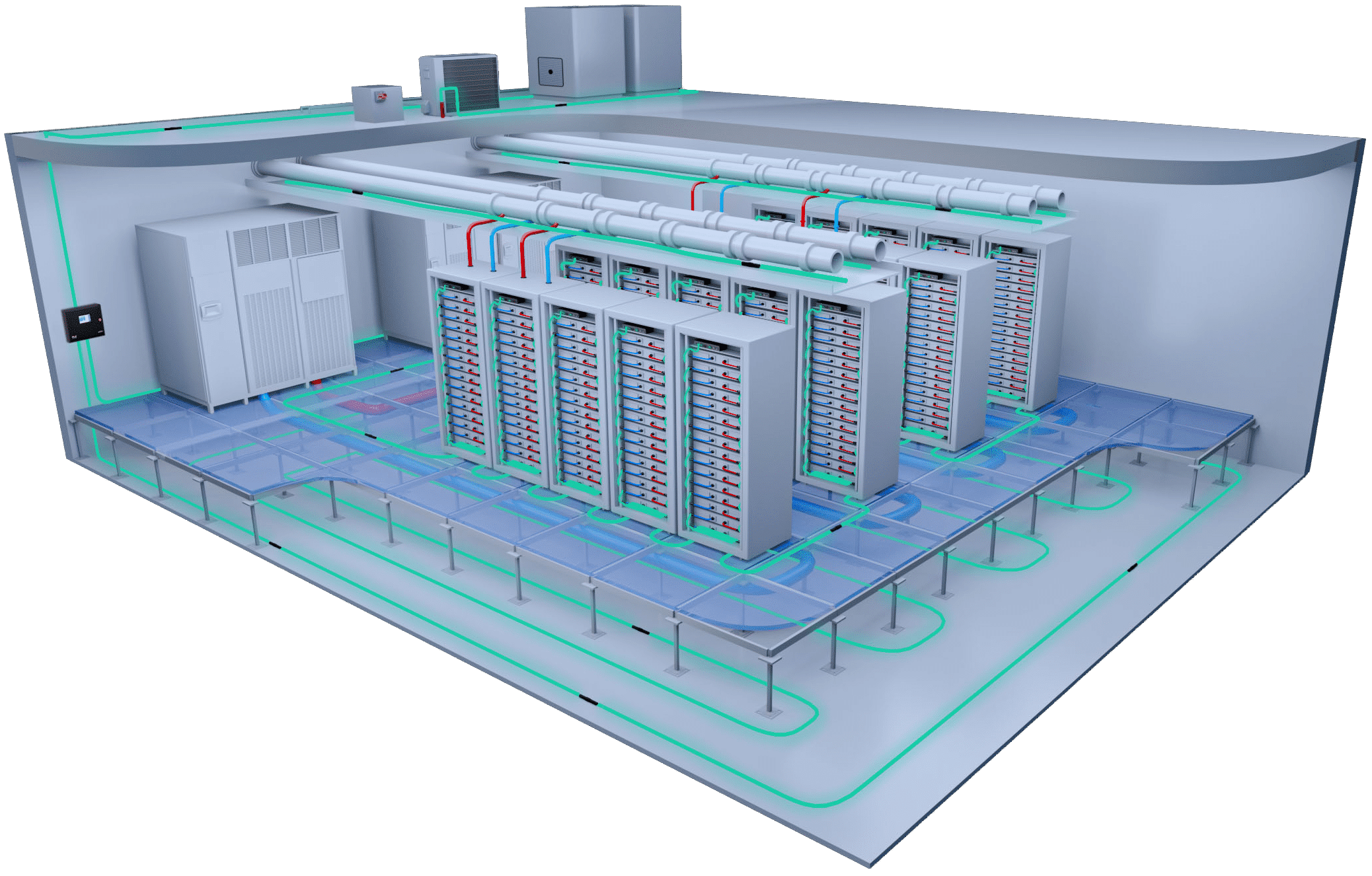

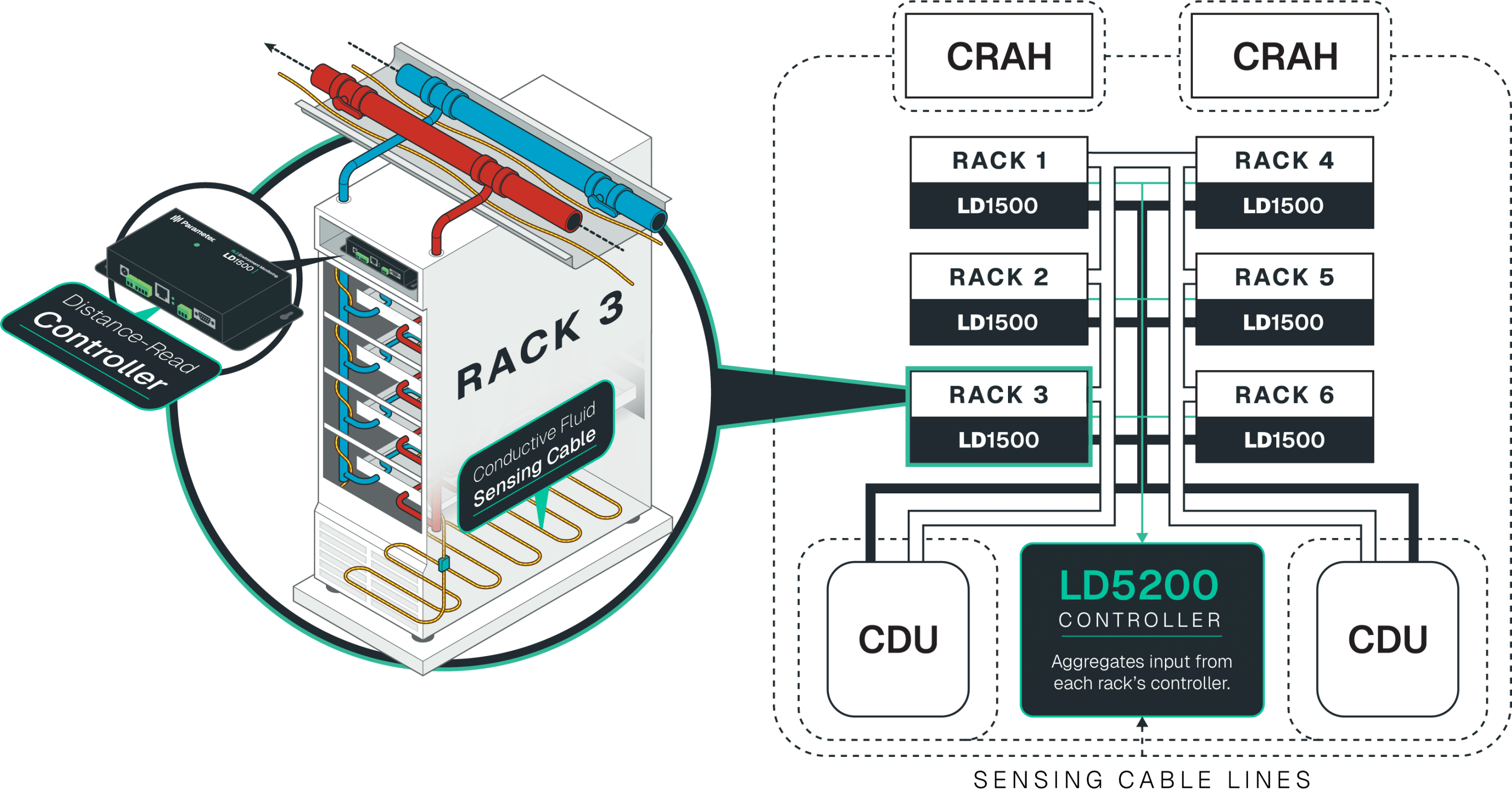

Parameter’s leak detection architecture is built for real-world data center deployment. We supply and manufacture the entire sensing solution, from cable and integration firmware to the controllers at the heart of our industry-leading leak detection system. Our architecture easily adapts to the two most common use cases:

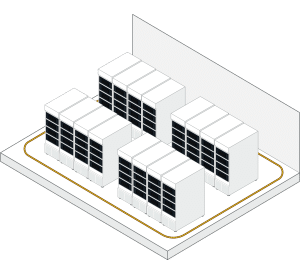

- Air-cooled data halls (long cable runs): one controller with long sensing-cable runs, reporting directly to the BMS.

- Liquid-cooled AI / high-density use case (distributed controllers): one controller per rack (or pod) with master/client aggregation for complete system visibility.

Controller |

Max Cable Length |

Mapping Capability |

Integration Protocols |

Interface Type |

Power Source |

Use Case / Application |

Cable Compatibility |

Data Sheets |

|---|---|---|---|---|---|---|---|---|

Controller |

Max Cable Length10,000 ft |

Mapping CapabilityYes |

Integration ProtocolsModbus, BACnet, SNMP, Relay |

Interface TypeWeb UI + LCD |

Power Source24VDC / PoE |

Use Case / ApplicationEnterprise, hyperscale, and distributed facilities. Aggregates up to 128 LD1500 units for per-rack leak detection in high-density or liquid-cooled environments. Ideal for distributed architecture in AI, HPC, and modular deployments. |

Cable CompatibilitySC, SC-C, SC-ZH |

Data Sheets |

Controller |

Max Cable Length5,000 ft |

Mapping CapabilityYes |

Integration ProtocolsModbus, BACnet, SNMP, Relay |

Interface TypeWeb UI + LCD |

Power Source24VDC / PoE |

Use Case / ApplicationMulti-zone data centers, campus environments |

Cable CompatibilitySC, SC-C, SC-ZH |

Data Sheets |

Controller |

Max Cable Length5,000 ft |

Mapping CapabilityYes |

Integration ProtocolsModbus, Relay |

Interface TypeLCD |

Power Source24VDC |

Use Case / ApplicationMid-size facilities, resettable alarms. deal for high-density racks using direct-to-chip liquid cooling. Mounts inside cabinet manifolds and interfaces with flow valves to automatically shut down coolant flow the instant a leak is detected — minimizing downtime and hardware risk. |

Cable CompatibilitySC, SC-C |

Data Sheets |

Controller |

Max Cable Length1,000 ft |

Mapping CapabilityNo |

Integration ProtocolsRelay |

Interface TypeLED |

Power Source24VDC |

Use Case / ApplicationCompact/small-scale detection needs |

Cable CompatibilitySC |

Data Sheets |

Controller |

Max Cable LengthUp to 200 ft (wireless spot) |

Mapping CapabilityYes(wireless spot location) |

Integration ProtocolsModbus, SNMP |

Interface TypeWeb UI |

Power Source24VDC |

Use Case / ApplicationWireless environments; integration via WiNG-MGR |

Cable CompatibilityWireless Spot Detectors Only |

Data Sheets |

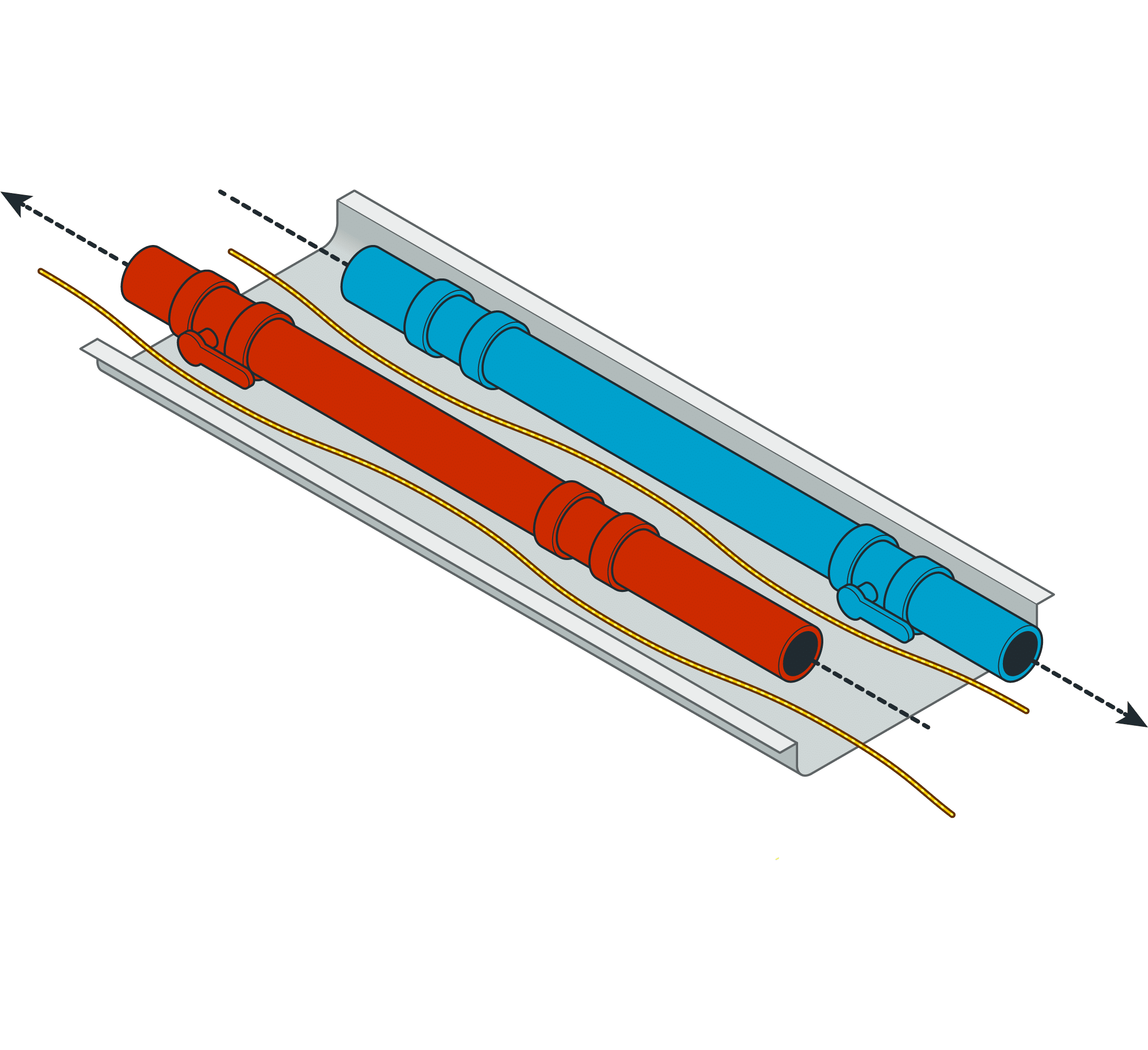

Sensing Cables

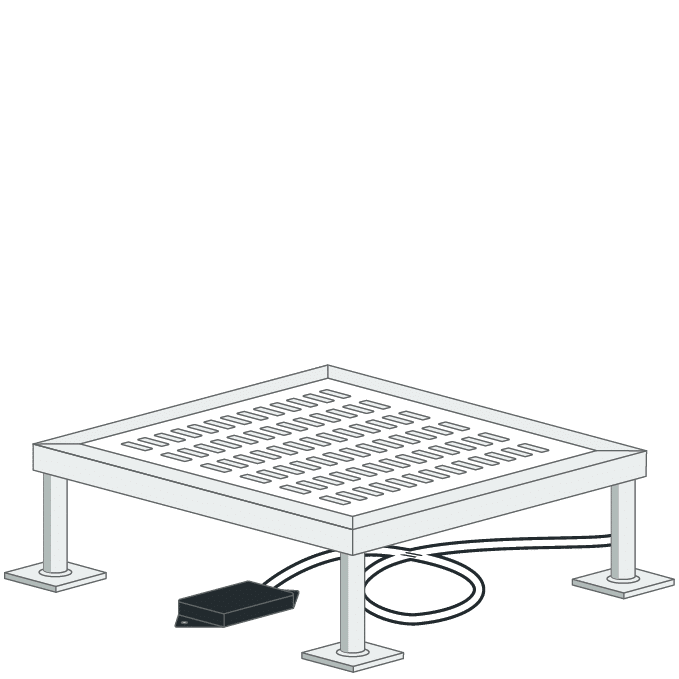

Parameter sensing cables are engineered for fast fluid detection and accuracy across long distances, including serpentine layouts and distributed topologies.

Designed for real-world deployments, these cables can be routed along room perimeters, beneath raised floors, affixed to overhead piping, or around high-risk equipment zones.

Each model detects conductive fluids through resistance-based current sensing, triggering location-based alerts.

Perimeter Monitoring

Direct-to-Chip Liquid Cooling

Coolant Pipes & Plumbing

Primary Cooling Units

Cable Type |

Use Case / Application |

Fluid Type Detected |

Key Features |

Data Sheet |

|---|---|---|---|---|

Cable Type |

Use Case / ApplicationConductive Fluid Sensing Cable |

Fluid Type DetectedWater and other conductive liquids |

Key FeaturesCore cable for most systems; triggers leak detection via cable current |

Data Sheet |

Cable Type |

Use Case / ApplicationChemical Sensing Cable |

Fluid Type DetectedAcids, bases, chemicals |

Key FeaturesGreen cable; resistant to corrosion; metal connectors |

Data Sheet |

Cable Type |

Use Case / ApplicationLow Smoke Zero Halogen (LSZH) Cable |

Fluid Type DetectedConductive fluids |

Key FeaturesMade with LSZH-rated polymers; meets LSZH IEC 60754-2 (Halogen Free), IEC 61034-1 (Low Smoke) |

Data Sheet |

Cable Type |

Use Case / ApplicationConductive Fluid Sensing Cable (with pest deterrent additives) |

Fluid Type DetectedWater and other conductive liquids |

Key FeaturesDesigned to discourage rodent chewing with chemical additives and specialized cable color; ideal for older buildings, outdoor routing, or vulnerable infrastructure |

Data Sheet |

Spot Detector

Spot detectors provide precise, localized fluid detection for edge environments and space-constrained deployments. These compact, surface-mounted sensors are ideal for areas where sensing cable isn't practical such as in HVAC drip pans, inside enclosures, or under isolated equipment

HVAC Drip Trays

Under Equipment

Tight Spaces

Inside Enclosures

All models integrate with Parameter controllers and trigger leak events upon fluid contact. Select models also support dry contact relay outputs or are optimized for OEM system builds.

Spot Detector Model |

Leak Type Detected |

Power Requirements |

Output Type (Connection Style) |

Enclosure Rating |

Ideal For |

Reset Method |

Use Case Details |

Data Sheet |

|---|---|---|---|---|---|---|---|---|

Spot Detector Model |

Leak Type DetectedWater |

Power Requirements5–48VDC |

Output Type (Connection Style)Relay (dry contact) |

Enclosure RatingIP66 |

Ideal ForGeneral-purpose water detection under raised floors or HVAC |

Reset MethodAuto-reset; no manual intervention |

Use Case DetailsCompact form factor with rapid response time. Ideal for general-purpose deployments where reliable water detection and simple integration are required. |

Data Sheet |

Spot Detector Model |

Leak Type DetectedWater |

Power Requirements5–48VDC |

Output Type (Connection Style)Relay (dry contact) |

Enclosure RatingIP66 |

Ideal ForTight spaces, standalone detection, or dry contact integration |

Reset MethodAuto-reset; no manual intervention |

Use Case DetailsScrew-mountable, low-profile design makes it a go-to for space-constrained areas. Can operate as a standalone detector or integrate with third-party dry contact systems. |

Data Sheet |

Spot Detector Model |

Leak Type DetectedConductive liquids (water, glycol) |

Power Requirements5VDC (from controller) |

Output Type (Connection Style)2-wire leak input |

Enclosure RatingNEMA 4X |

Ideal ForOEM installations, industrial use w/ modular cable |

Reset MethodAuto-reset via controller once leak clears |

Use Case DetailsSpecifically engineered for OEM applications. Pairs seamlessly with SC-type modular sensing cables and is commonly used with LDRA6-style panel integration. |

Data Sheet |

Spot Detector Model |

Leak Type DetectedWater + Chemicals (e.g., oils, fuels) |

Power Requirements5VDC (from controller) |

Output Type (Connection Style)2-wire leak input |

Enclosure RatingNEMA 4X / Chemical Resistant |

Ideal ForIndustrial / chemical plant applications |

Reset MethodAuto-reset via controller once leak clears |

Use Case DetailsBuilt for chemically aggressive environments. Requires use of FSCR chemical-rated sensing cable for accurate detection of fuels, oils, and industrial fluids. |

Data Sheet |

Accessories & Integration Components

Parameter’s leak detection architecture is engineered for real-world deployment where performance hinges not just on sensors, but the hardware that connects, powers, and communicates between them. These components ensure:

Cable continuity with precision mapping:

Leader cables preserve the sensing run for critical zones, while end terminators confirm circuit integrity and prevent false alerts — even across thousands of feet.

Direct-to-BMS integration with embedded protocols:

Native BACnet MS/TP, BACnet/IP, Modbus RTU, Modbus TCP, and SNMP, plus relay outputs and a built-in web UI. Protocols and the interface run locally on the controller, so no subscriptions are required, and the system is fully compatible with third-party BMS/DCIM platforms.

OEM-ready adaptability:

Modular interface options and dry-contact compatibility allow tight integration into SCADA, HVAC, and custom enclosures.

Whether you're tying into a BMS or DCIM, routing cable through dense infrastructure, or adding backup power to maintain controller uptime, these components are built to reduce failure points and simplify deployment. Their durability and performance have been proven across real-world installations.

For custom capabilities and manufacturing, reach out to our OEM team directly to discuss how we can augment your application.

System Architecture

Parameter’s leak detection architecture is built from the ground up for real-time responsiveness, precision mapping, and uncompromising reliability — even in noisy, high-stakes environments. Our controllers continuously monitor resistance-based sensing cables and support flexible configuration including both flat direct-to-BMS topology and hierarchical master/client controller aggregation topology. This enables easy scalability and effective monitoring of high-density applications such as direct-to-chip liquid cooling.

One LD1500 controller per flow valve.

The LD1500 controller also provides convenient alerts and status updates via an easy-to-use web interface accessible from any browser or mobile device.

Key Advantages

Multi-protocol native integration

Seamless communication via BACnet MS/TP, Modbus RTU, BACnet IP, Modbus TCP, SNMP, on both ethernet and RS-485. No middleware, converters, or protocol compromises.

Linear and branched topologies

Modular cable layouts simplify installation while maintaining precise mapping fidelity.

Direct cable-to-controller signal path

Engineered for speed and clarity, our system minimizes latency between detection and alert. Signal propagation is nearly instantaneous, reducing risk during critical events in high-impact environments such as healthcare, hyperscale, or government infrastructure.

Signal stability under noise

Shielded cable design and built-in signal buffering protect against EMI from UPS equipment, switchgear, or HVAC — ensuring detection integrity even in electrically noisy environments.

Integrated Web Servers

No cloud dependency, forced subscriptions, or third-party config.

Real-time fault detection and auto-reset logic

Controllers localize the leak, register cable position, and instantly initiate BMS communication. The system auto-clears upon leak removal, minimizing technician intervention and enabling faster recovery.

From leak contact to alarm to mapped location, the system delivers clear, actionable signals whether you deploy long runs across air-cooled halls or distributed controllers at rack level for liquid-cooled AI. This maintains consistency with the way facilities actually operate, making it easy to scale from a single room to a hyperscale campus.