Environment Monitoring

Critical applications depend on reliable equipment and comprehensive threat resolution to ensure your operation continues without interruption. Accurately assessing risks before they compromise operation requires continuous, detailed visibility throughout your facility

Operational

Visibility

On average, data center downtime costs upwards of $8,000 per minute. Short interruptions can have expensive consequences, and small environmental changes can have disastrous repercussions. Minimizing and preventing downtime is all about quickly and accurately detecting points of failure.

Quantifying Downtime

Data Insight

Activity-Based Cost

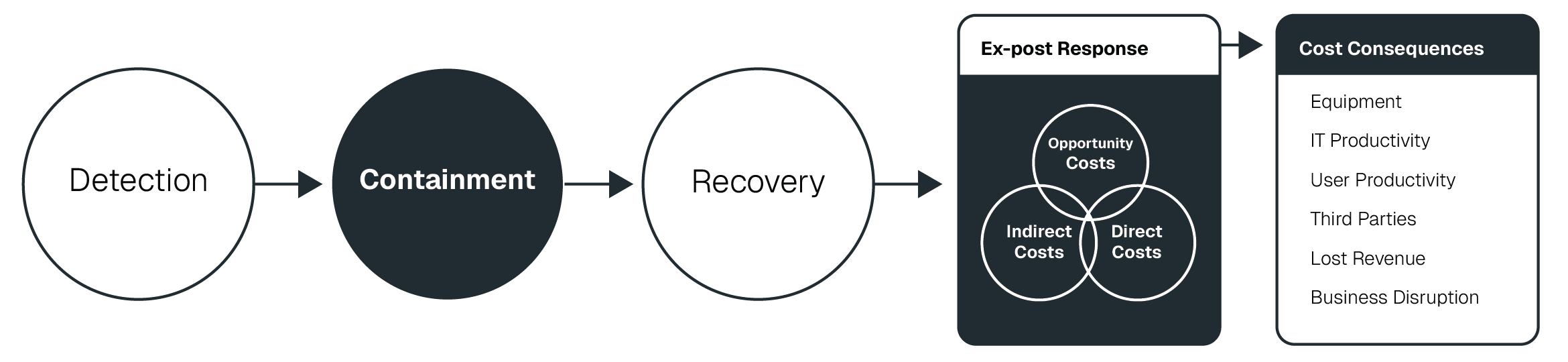

MULTIPLYING LOSSES: Downtime costs are calculated as a function of time, with consequences worsening as inaction continues. Issues that cause downtime can spread quickly, so the longer detection takes, the longer containment and recovery efforts will take. This means that compromised systems will continue to double total estimated losses until the error is detected. When downtime averages an $8000 cost per minute, financial impact can snowball quickly.

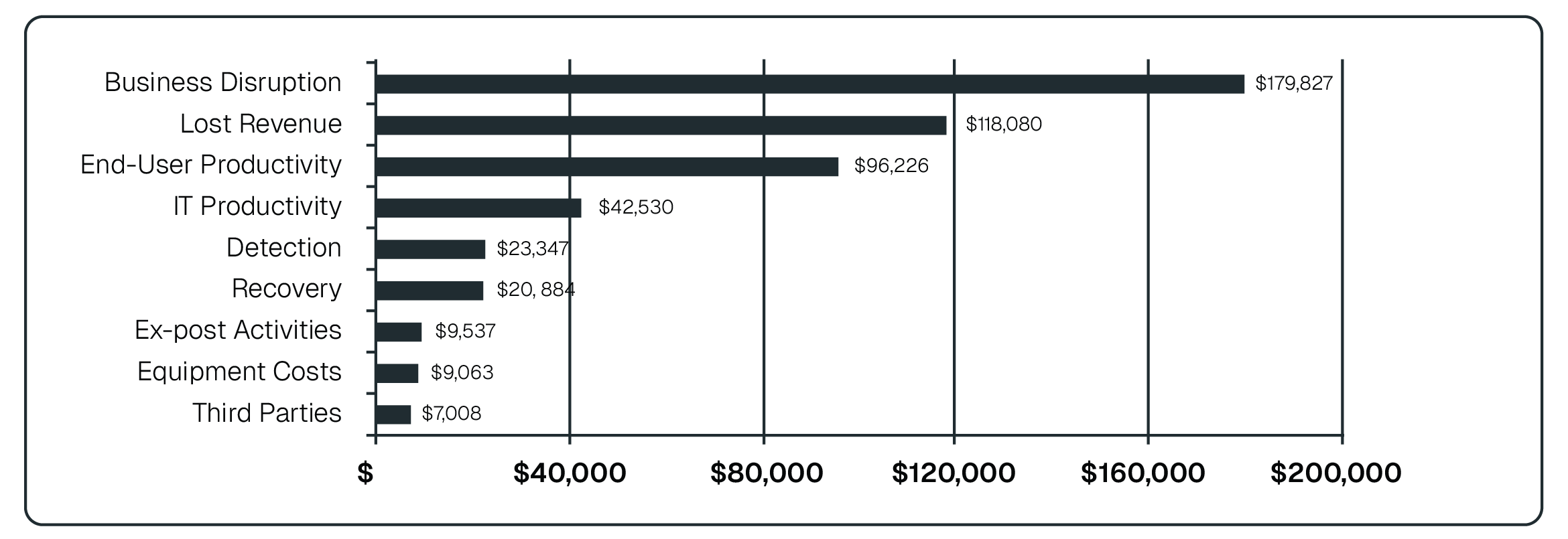

While unexpected downtime events can lead to significant asset or equipment losses, over 60% of the average financial impact comes from indirect and opportunity costs. In most cases, these stem not from catastrophic failures, but from undetected vulnerabilities in power, cooling, and environmental systems. It is the small, unexpected disruptions that typically cost critical facilities the most in the long run.

AVERAGE LOSSES: The following graph breaks down the average total losses from a single 90-minute downtime event at a mid-sized data center.

MULTIPLYING LOSSES: Downtime costs are calculated as a function of time, with consequences worsening as inaction continues. Issues that cause downtime can spread quickly, so the longer detection takes, the longer containment and recovery efforts will take. This means that compromised systems will continue to double total estimated losses until the error is detected. When downtime averages an $8000 cost per minute, financial impact can snowball quickly.

Data courtesy of Vertiv

Parameter Solutions

Parameter’s Environmental monitoring solutions provide you with comprehensive, real-time visibility into every critical aspect of your infrastructure, enabling you to manage and optimize your operations more effectively.

We offer wide coverage sensors to monitor all critical aspects of your factility.

RLE Environment Monitoring by Parameter

Hazards

Read More

TEMP & HUMIDITY: The WIRED-TH is a wall-mountable wired temperature and humidity that can be used in conjunction with the FMS to monitor and display information.

LEAK DETECTION: The WiNG-LD wireless sensor can be coupled with an SD-Z or SD-Z1 spot detector or any of our leak detection sensing cables to detect and report leaks in any facility.

SMOKE: The SMK is a wired photoelectric smoke detector that can be used in conjunction with the FMS, F200, or WiNG-MGR to monitor for smoke.

Conditions

Read More

CARBON DIOXIDE: The WiNG-CO2 wirelessly measures carbon dioxide, temperature, and humidity and can detect impeded airflow, stalled fans, leaks, blockages, or clogged filters.

AIR PRESSURE: The WiNG-DAP wirelessly monitors air pressure to help you better understand how air flows around your environment and validate infrastructure and airflow changes.

AIR VELOCITY: Parameter offers three WiNG air velocity sensors: the economical WiNG-AIR3, the high-precision WiNG-AIR4, and wide-ranged BMS-AIR10.

Signals

Read More

POWER FAIL: The power fail monitor (PFM) monitors any standard outlet and provides early warning that power has been lost.

DIGITAL INPUT: The WiNG-DI sensor allows you to take a wired digital input and convert it to a wireless signal that can be implemented into a WiNG-MGR or BMS-WiNG monitoring system.

ANALOG INPUT: The WiNG-ANLG sensor allows you to take a wired analog input and convert it into a wireless signal that can be implemented into a WiNG-MGR monitoring system.

MOTION & DOORS: The MD3 is a wired motion sensor while the MDS is a wired magnetic door sensor. Both can be used in conjunction withe FMS, F200, or WiNG-MGR.

Comprehensive Coverage

Our monitoring equipment tracks key factors such as temperature, humidity, airflow, water leaks, chemical leaks, C02, smoke, motion, battery health, and power outages, ensuring that all environmental conditions remain within the desired parameters.

Reliable and Accurate Equipment

We take care to ensure our products are the best on the market. When monitoring critical equipment there is no room for unreliable results. That’s why for the past 30 years, our clients have consistently praised our quality as second to none.

Data-Driven Decisions

Our monitoring platforms offer real-time data and actionable insights, helping you quickly resolve hazards, prevent failures, and make informed decisions regarding equipment and facility management.

Seamless Integration

Our wireless sensors and proprietary controllers can connect disparate hardware and protocols to provide a unified monitoring solution seamlessly integrated with your BMS.

Adaptability

We strive to provide the best solution for your facility, and not all facilities are the same. Our advanced integration technology and in-house manufacturing capabilities ensure we can supply a solution that fits the specific needs of your operation.

Resources

PRODUCT INFO: Click below to review our leak detection products, data sheets, and application papers.

Monitoring At Scale

Centralize Your Operation

On average, data center downtime costs upwards of $8,000 per minute. Short interruptions can have expensive consequences, and small environmental changes can have disastrous repercussions.

Minimizing and preventing downtime is all about quickly and accurately detecting points of failure.

Minimizing and preventing downtime is all about quickly and accurately detecting points of failure.