Leak

Detection

Fluid leaks are a major threat to any critical infrastructure. Liquid hazards often appear quickly and cause equipment malfunction, downtime, and system failure within minutes.

If liquid detection is overlooked in critical applications, it often causes damages to be unaddressed until irreparable harm has already been done.

Safeguard Critical

Infrastructure

Crucial operating systems are often surrounded by infrastructural leak threats that need to be properly safeguarded and monitored for failure.

COOLING LIQUIDS: In high-density applications that generate excessive heat, coolant leaks are likely to occur near the most vulnerable parts of your high-value assets. Immediate and distributed detection and flow control is crucial to minimizing losses when these leaks occur.

HVAC / PLUMBING: Overhead pipes and coolant supply tubing can fail even in stable environments, leaking gallons of liquid onto sensitive equipment or toxic substances into occupied areas.

Chemical: In the event of a leak, hazardous chemicals can deteriorate or destroy system infrastructure, release flammable gas into the environment, and poison personnel. Early warning is necessary to resolve the leak before it compromises other systems or triggers an evacuation.

Parameter’s leak detection solutions are powered by RLE Leak Detection and offer comprehensive monitoring for water, coolant, and chemical leaks that threaten the integrity of your facility.

By providing early detection and real-time alerts, our systems ensure that you can respond quickly to prevent catastrophic failures.

Sensing Cables

Details

FLUID SENSING CABLE: Our conductive fluid leak detection sensing cable (SC) detects the presence of water leaks and other conductive fluids.

CHEMICAL SENSING CABLE: Our green chemical sensing cable is used to detect leaks via the presence of acids, bases, and other conductive liquids. It is reliable and durable, resistant to chemical corrosion, and offers fast reaction time.

LOW SMOKE ZERO HALOGEN: Our low smoke zero halogen (LSZH) sensing cable detects water leaks and other conductive fluids. Constructed from non-conductive polymers to help eliminate false alarms, its composition is formulated to receive a low smoke zero halogen (LSZH) materials classification.

Spot Detectors

Details

SPOT DETECTORS: Our spot detectors are reliable single-location, high-sensitivity fluid sensors. For areas where predictable leaks may occur, these sensors provide unmatched reliability.

Our spot detectors integrate with zone-read and distance-read controllers, simpulating up to 50 ft of sensing cable.

Controllers

Details

DISTANCE READ: Our distance read controllers pair superior leak detection technology with an easy-to-use interface. This integration helps users efficiently establish a distance-read leak detection system that monitors up to 10,000 feet of sensing cable.

ZONE READ: Our single-zone leak and water detection controllers monitor up to 1,000 feet of sensing cable. They use zone-segmented readouts and audible / visual alarms to make failure points quick and easy to identify.

Easy Integration

Our sensors and controllers easily integrate with your BMS and merge 3rd party protocols into a secure web-based monitoring platform with no additional subscription costs.

Installation

Our systems are plug-and-play. They integrate easily with third party protocols without software adjustment and operate reliability for the lifetime of your system. Once deployed, it just works

Reuse

Our detection cables are resettable, reusable, and durable. They dry easily, last longer, and are reset quickly, so your operation can resume without delays or replacement costs.

Accuracy

Our equipment is engineered for high performance and unfailing reliability. Parameter detection cables have an accuracy of ±2 feet / ±0.5% of cable length along with map-applied distance read for easy leak detection, they are sensitive enough to detect even small spills, and engineered to eliminate false alerts.

Coverage

Our comprehensive product line provides full coverage in any facility, allowing for accurate detection along 10,000ft of detection cable and wireless range up to 1600ft to ensure your entire facility is effectively monitored.

Resources

PRODUCT INFO: Click below to review our leak detection products, data sheets, and application papers.

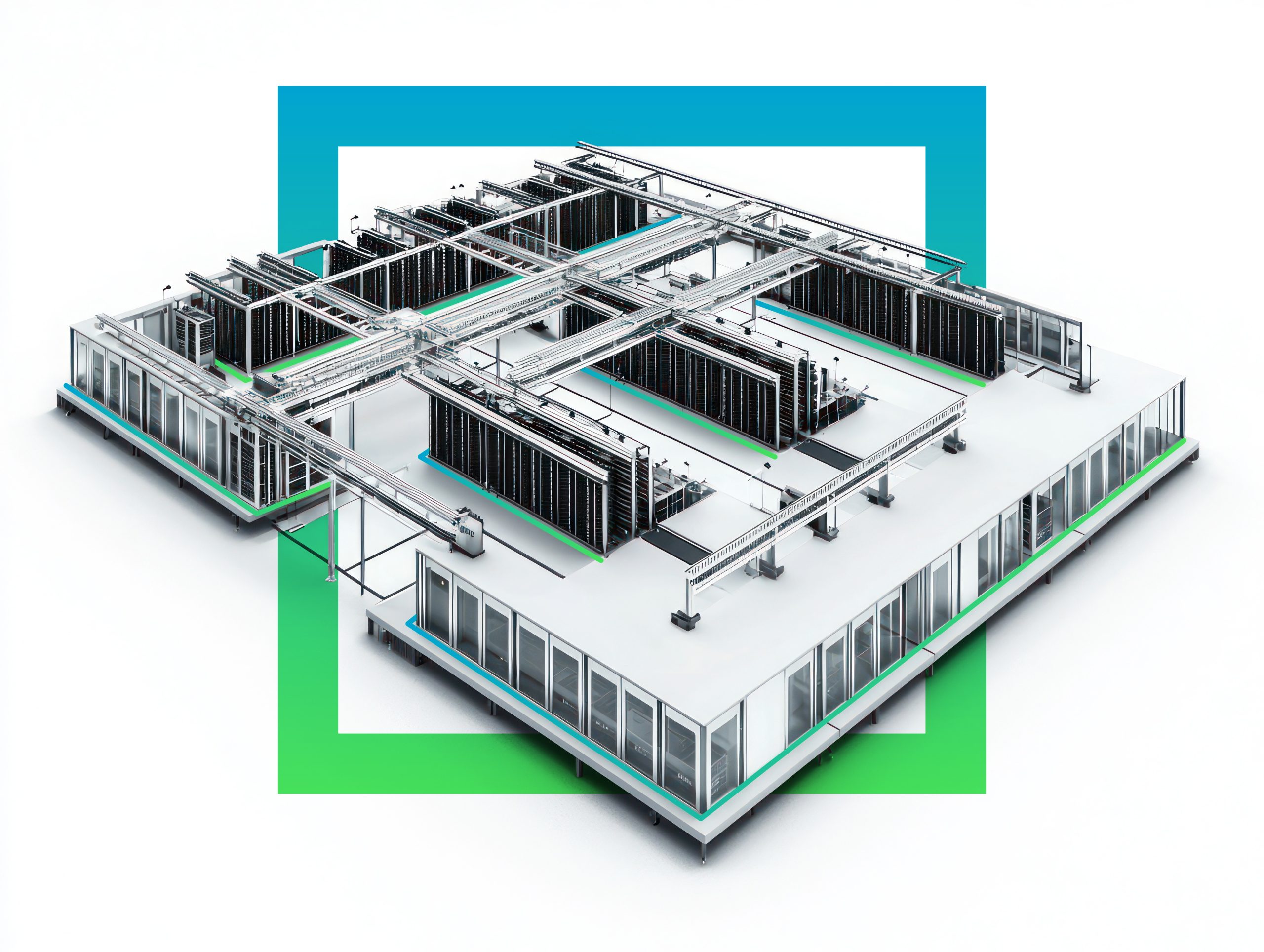

Liquid Cooling

High-Density Liquid Cooled

Data Centers

With increasing power-per-rack demand in data center development, Direct-to-Chip cooling is rapidly gaining popularity and proving itself as a new standard for the market. How can you implement this technology safely into your operation?

CRITICAL APPLICATION: Direct-to-Chip cooling intimately integrates conductive coolant with the most vulnerable layer of your server. The key to benefitting from the advanced thermal management is ensuring reliability against failure. At scale, there are many considerations to keep in mind.

THE DANGER OF LEAKS: A small, undetected leak in a liquid cooling system can cause catastrophic damages to critical assets, disrupt operation, and impact facility-wide systems. Many of these systems are not designed to identify liquid damage at the server level until an entire rack loses functionality.

POTENTIAL LOSSES: Coolant system failure is the second most common cause of server outage. In an application where data is critical and downtime costs $5,600 per minute on average, there is no substitute for immediate action.

Talk to Us About Direct-to-Chip Leak Detection

In an application so closely integrated to server-level manufacturing, reliability is crucial to limiting maintenance costs and reducing downtime. That’s why Parameter’s solutions are powered by RLE Leak Detection, the industry leader for leak detection innovation and quality.

ACTIVE FLOW CONTROL: By integrating leak detection sensors directly into the cooling system, Parameter helps you detect leaks as soon as they occur and stop coolant flow to prevent further damage.

REAL-TIME ALERTS: Our system provides real-time alerts, enabling immediate action and minimizing the impact of any potential failures.

SEAMLESS INTEGRATION: Our leak detection systems integrate with non-standard protocols, allowing for easy installation in existing coolant systems.

CUSTOM APPLICATION: Our US-based manufacturing makes it easy to provide custom equipment for application specific needs or OEM production at any scale.