Our systems power mission critical infrastructure with a unified monitoring system designed to identify disasters before they happen.

Our dedication to the core principles our clients value most guides our continual improvement and unmatched operational performance.

RELIABILITY

Dependable, industry-leading products that you can rely on.

FLEXIBILITY

Customizable solutions designed to fit your operation.

INTEGRATION

Seamless compatibility with your existing systems.

COVERAGE

We cover critical infrastructure throughout your facility.

RELIABILITY

Dependable, industry-leading products that you can rely on.

RELIABILITY

Dependable, industry-leading products that you can rely on.

RELIABILITY

Dependable, industry-leading products that you can rely on.

RELIABILITY

Dependable, industry-leading products that you can rely on.

70 Years of Excellence

in Facility Monitoring

Fusing 70 years of industry application experience, Parameter’s solutions are powered by the best in class technologies developed and continually evolved by subject matter experts over the decades.

Battery

Monitoring

Proactively manage battery health and receive real-time insights for mission-critical systems.

Environment

Monitoring

Early warning hazard monitoring that seamlessly integrates sensor telemetry directly into your building management system.

Leak

Detection

Precise and reliable leak detection solutions from the industry’s leading manufacturer.

Product Lines

Data Sheets

Specific Capabilities

Cellwatch Battery Monitoring

Passive battery maintenance for continuous cell monitoring to identify battery health issues before they lead to disaster.

Cellwatch Central

Comprehensive and secure multi-site monitoring platform for checking backup power system health remotely.

Cellwatch Frontier

NERC-Compliant automated battery maintenance and reporting system for utility power applications.

RLE Leak Detection

Robust and reliable fluid sensing cables, spot detectors, and controllers for high-density critical infrastructure.

RLE Environment Monitoring

Industry-leading sensors and controllers that offer native multi-protocol support for seamless BMS integration.

Triad Flooring

Comprehensive raised floor ecosystem and product line optimized for efficient airflow circulation.

uNIVERSAL aPPLICATION

Infrastructure

BMS Integration

OPERATIONAL OVERSIGHT: Parameter’s sensing technology seamlessly integrates with your building management system with no software adjustments. Our controllers act as waystations that connect our products and 3rd party sensing equipment, reconcile differing inputs, and output a centralized data stream that integrates natively with your system’s operating system.

Paired with our Wi-Fi enabled transmitters and web-based alert platforms, clients can securely monitor their entire facility remotely and receive all hazard alerts in one location. These systems can be installed privately on your local network, or hosted for easy overview of multi-site operations.

Equipment

mULTI-pROTOCOL

NATIVE SYSTEM COMMUNICATION: Our integration equipment natively accepts SNMP, BACnet, and Modbus protocols simultaneously. Our system can seamlessly convert any of these protocols to any of the others losslessly and without delays, eliminating missed readings and complex software work-arounds.

Our controllers connect equipment operating on disparate protocols and allow them to communicate with your building management system or other controller systems under a single pane of glass.

Operation

Signal Unification

CENTRALIZED MONITORING: Our alarm signaling devices make it easy to take an alarm condition identified by Parameter products or 3rd party devices and distribute that alarm signal to other applications throughout your facility. For facilities with separate building management systems, security systems, and network management systems, this solution assures the lines of communication are open between all disparate systems and personnel, so the right people can identify the threat immediately and act without delay.

This centralized monitoring integration reduces missed alerts from disparate systems, eliminates silos by streamlining infrastructure management, and empowers analytic insights with consolidated facility operational data.

Discover how we integrate with your facility to achieve higher uptime, reduced costs, and better overall performance.

Learn More About Facility Monitoring Sensors and Controller Hardware.

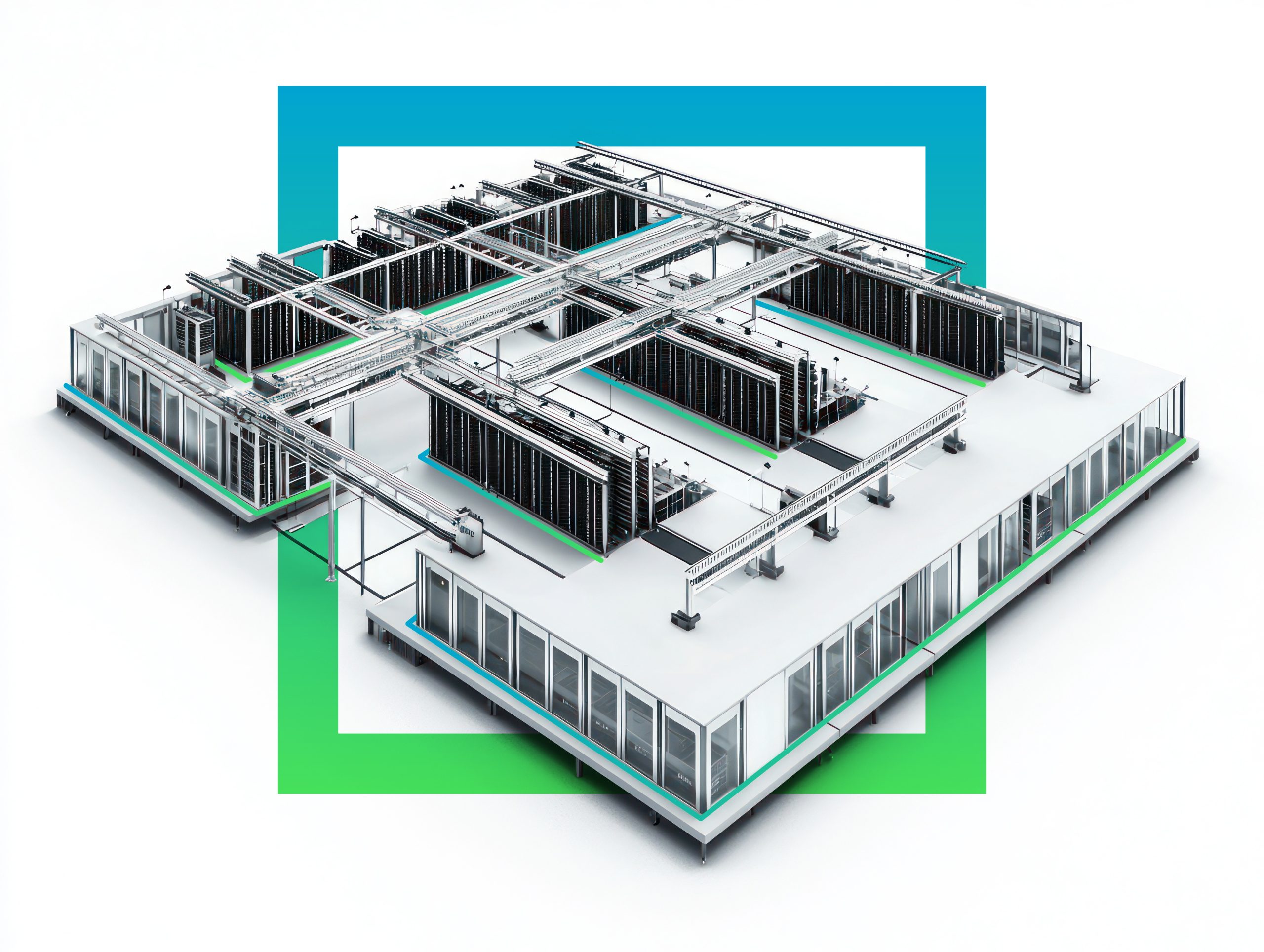

Data Centers

Flexible Solutions for Every Data Center Development and Operation.

From hyperscale to colocation and enterprise data centers, we offer flexible, scalable monitoring solutions

Hyperscale

As demand for data and computing power surges, hyperscale data centers are at the forefront of this transformation. These large-scale operations require robust, scalable monitoring systems that can handle thousands of assets spread across vast, complex infrastructures.

Parameter offers flexible, reliable, future-proof solutions designed to scale with your operations and meet the growing demands of hyperscale data centers. Our platform ensures seamless integration, real-time monitoring, and automated alerting for optimal performance and reliability.

Colocation

Colocation data centers are the backbone of the digital economy. As more businesses migrate to colocation services, providers must adapt to the rapid growth and provide custom operational and infrastructural capabilities to accommodate client needs.

For these facilities, Parameter offers highly customizable monitoring solutions that accommodate multiple tenants and integrate with different equipment types and protocols. Our platform is vendor-neutral and flexible, ensuring that each client’s unique needs are met while maintaining overall facility performance. With real-time environmental and asset monitoring, you can provide peace of mind to your customers, knowing their critical systems are protected 24/7.

Enterprise

Enterprise data centers house sensitive, mission-critical data that must be secured, maintained, and protected at all costs. Parameter’s monitoring solutions for enterprise environments ensure that operations run efficiently while minimizing risks associated with security breaches, downtime, and equipment failure.

With reliable solutions and easy integration, we empower enterprises to monitor and manage their power, cooling, and battery systems with real-time alerts and data-driven insights. Our solutions are designed to ensure business continuity, reduce costs, and enhance security for sensitive infrastructure.

Highlighted Technology

Liquid Cooling

High-Density Liquid Cooled

Data Centers

With increasing power-per-rack demand in data center development, Direct-to-Chip cooling is rapidly gaining popularity and proving itself as a new standard for the market. How can you implement this technology safely into your operation?

CRITICAL APPLICATION: Direct-to-Chip cooling intimately integrates conductive coolant with the most vulnerable layer of your server. The key to benefitting from the advanced thermal management is ensuring reliability against failure. At scale, there are many considerations to keep in mind.

THE DANGER OF LEAKS: A small, undetected leak in a liquid cooling system can cause catastrophic damages to critical assets, disrupt operation, and impact facility-wide systems. Many of these systems are not designed to identify liquid damage at the server level until an entire rack loses functionality.

POTENTIAL LOSSES: Coolant system failure is the second most common cause of server outage. In an application where data is critical and downtime costs $5,600 per minute on average, there is no substitute for immediate action.

Talk to Us About Direct-to-Chip Leak Detection

In an application so closely integrated to server-level manufacturing, reliability is crucial to limiting maintenance costs and reducing downtime. That’s why Parameter’s solutions are powered by RLE Leak Detection, the industry leader for leak detection innovation and quality.

Talk to Us About Direct-to-Chip Leak Detection

In an application so closely integrated to server-level manufacturing, reliability is crucial to limiting maintenance costs and reducing downtime. That’s why Parameter’s solutions are powered by RLE Leak Detection, the industry leader for leak detection innovation and quality.

ACTIVE FLOW CONTROL: By integrating leak detection sensors directly into the cooling system, Parameter helps you detect leaks as soon as they occur and stop coolant flow to prevent further damage.

REAL-TIME ALERTS: Our system provides real-time alerts, enabling immediate action and minimizing the impact of any potential failures.

SEAMLESS INTEGRATION: Our leak detection systems integrate with non-standard protocols, allowing for easy installation in existing coolant systems.

CUSTOM APPLICATION: Our US-based manufacturing makes it easy to provide custom equipment for application specific needs or OEM production at any scale.